Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

The energy consumption of China Stationary Crusher has become a critical topic in the era of sustainable development and environmental conservation. As the construction and mining industries continue to expand, the role of these crushers in processing raw materials becomes increasingly significant. This article delves into the energy efficiency of China Stationary Crushers, examining factors that contribute to their power usage and exploring potential solutions for reducing energy consumption.

China Stationary Crusher, a vital component in the processing of various materials, is designed to handle large volumes of rock, ore, and other materials. The energy consumption of these crushers is a significant factor in the overall operational costs and environmental impact of the industries they serve. Understanding the energy requirements of China Stationary Crushers is essential for optimizing their performance and reducing their carbon footprint.

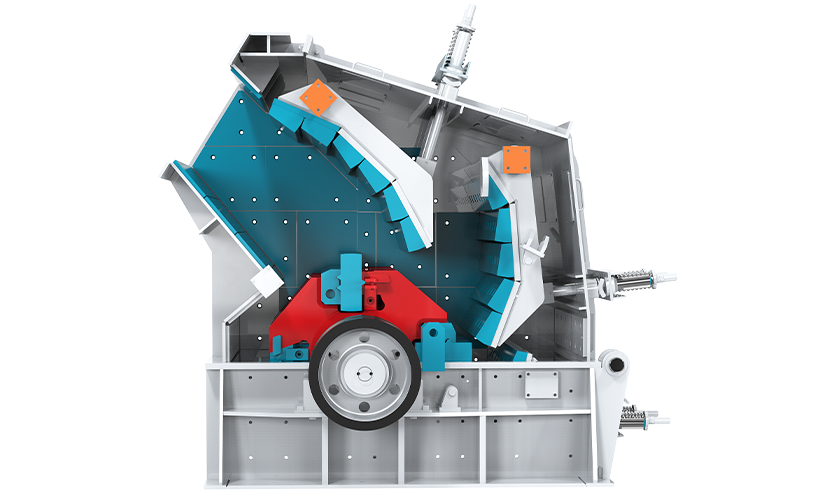

The primary energy source for China Stationary Crusher is electricity, with some models also utilizing diesel for auxiliary power. The energy consumption of these crushers is influenced by several factors, including the type and size of the crusher, the hardness and size of the material being processed, and the operational settings such as speed and feed rate. Larger crushers, which are more common in mining applications, tend to consume more energy due to their increased capacity and the larger motors required to drive them.

Efficiency in China's Stationary Crusher operations is not only about the amount of energy consumed but also about the output produced. A crusher that consumes less energy while maintaining high output is considered more efficient. Modern crushers are equipped with advanced technologies such as variable frequency drives (VFDs) that allow for the adjustment of motor speed to match the workload, thereby reducing energy consumption during periods of low demand.

Another aspect of energy consumption in China Stationary Crusher is the heat generated during operation. Proper heat management is crucial to prevent damage to the crusher's components and to maintain efficiency. Cooling systems, such as water or air cooling, are often integrated into the design to dissipate heat and keep the crusher's temperature within safe operating limits.

The design and material selection of China Stationary Crusher also plays a role in energy consumption. Crushers with more efficient designs, such as those with better-crushing chambers and wear-resistant materials, can process materials more effectively, reducing the energy required to achieve the same output. Additionally, the use of recycled materials in the construction of crushers can contribute to a lower overall environmental impact.

Maintenance practices also have a direct impact on the energy consumption of China Stationary Crusher. Regular maintenance, including the timely replacement of worn parts and the lubrication of moving components, can ensure that the crusher operates efficiently. Neglecting maintenance can cause increased energy consumption due to increased friction and reduced efficiency.

In conclusion, the energy consumption of China Stationary Crusher is a multifaceted issue that requires a comprehensive approach to address. By understanding the factors that influence energy usage and implementing strategies to improve efficiency, the mining and construction industries can reduce their operational costs and environmental impact. As technology advances and the focus on sustainability intensifies, the development of more energy-efficient China Stationary Crusher will continue to be a priority in the industry.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!