Industry Knowledge Extension

How does the hydraulic system of a cone crusher function?

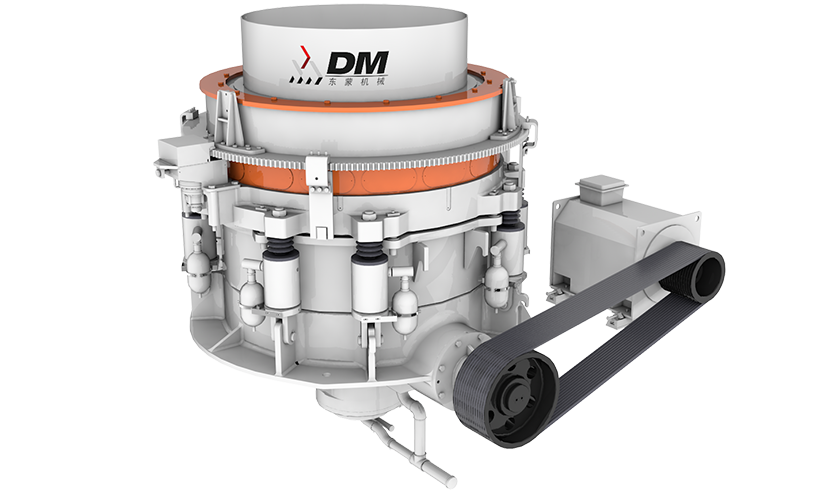

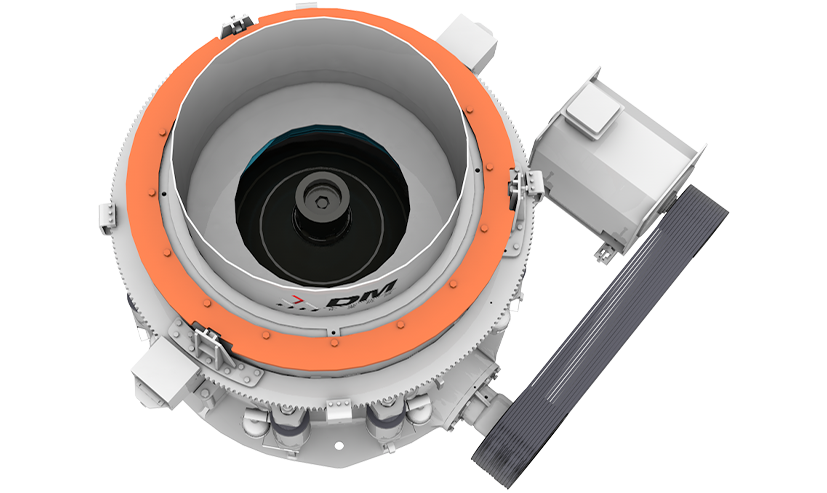

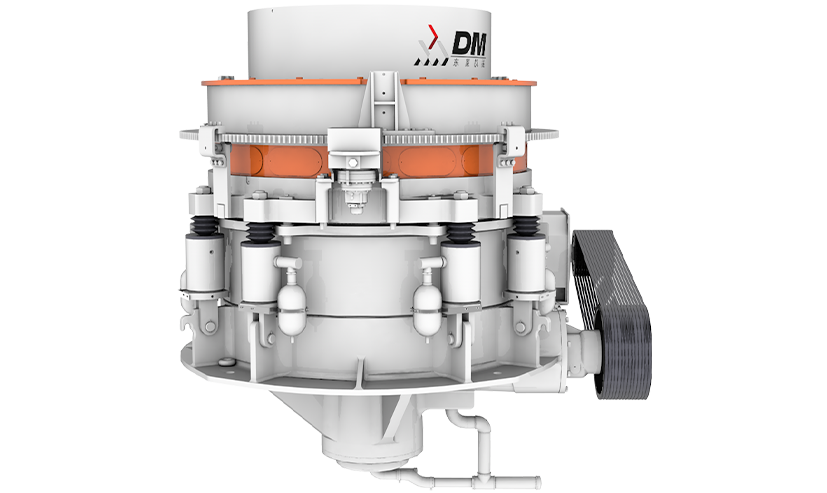

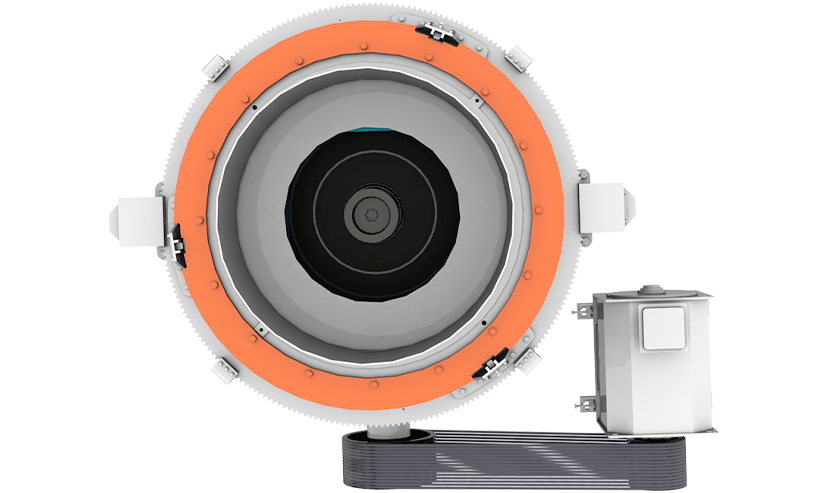

The hydraulic system of a cone crusher is responsible for controlling the movement of the crushing cone, as well as adjusting its position and size. The system is composed of several components, including:

Hydraulic pump: This component is responsible for providing the hydraulic fluid that powers the system.

Hydraulic motor: This component converts the hydraulic fluid's energy into mechanical energy to drive the crushing cone.

Hydraulic cylinder: The hydraulic cylinder is responsible for adjusting the position and size of the crushing cone. The cylinder's movement is controlled by the hydraulic fluid under pressure.

Control valve: The control valve regulates the flow of hydraulic fluid between the hydraulic pump and cylinder. It can adjust the pressure and flow rate of the hydraulic fluid to ensure the optimal operation of the system.

Accumulator: The accumulator stores hydraulic fluid under pressure, which can be used to provide additional force when needed. It also helps to maintain a constant pressure within the system.

When the cone crusher is in operation, the hydraulic pump generates hydraulic fluid that flows through the system. The control valve regulates the flow of hydraulic fluid to the hydraulic cylinder, which adjusts the crushing cone's position and size. The accumulator stores hydraulic fluid under pressure, which can be used to provide additional force when needed.

Overall, the hydraulic system of a cone crusher allows for precise control over the movement and size of the crushing cone, enabling efficient and effective crushing of materials.

How does the speed of the crusher affect the performance of the DHY hydraulic cone crusher?

The speed of a hydraulic cone crusher can have a significant impact on its performance. Generally, a higher crusher speed can result in:

Increased throughput: A faster crusher speed means that more material can be processed in a given amount of time, leading to higher throughput.

Finer product size: A higher crusher speed can produce a finer product size because the material spends less time in the crushing chamber.

Reduced operating costs: A faster crusher speed can reduce the wear on the crushing surfaces, leading to longer component life and lower maintenance costs.

However, there are also some potential drawbacks to a higher crusher speed, including:

Increased noise and vibration: A faster crusher speed can result in increased noise and vibration, which can be a concern for operators.

Reduced liner life: A higher crusher speed can result in increased wear on the crusher liners, reducing their lifespan.

Reduced product quality: A higher crusher speed can sometimes result in a coarser product size or a product with a wider size distribution.

Therefore, when selecting a crusher speed, it is important to consider the trade-offs between increased throughput and potential drawbacks such as increased wear, noise, and vibration. The optimal crusher speed will depend on the specific application and the characteristics of the material being processed.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to