Industry Knowledge Extension

What is a rotary crusher, and how does it work?

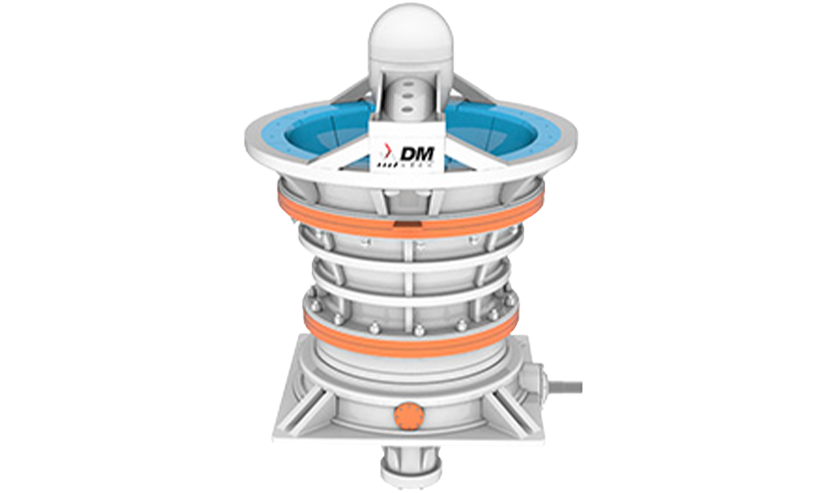

A rotary crusher, also known as a rotary breaker or rotary crushing machine, is a type of crusher that breaks down materials by impact or attrition using a rotating cylinder with hammers or blades inside.

The cylinder is typically made of steel and rotates at a high speed. As the materials are fed into the cylinder, they are impacted by the hammers or blades, which break them into smaller pieces. The size of the materials is further reduced as they collide with each other and with the walls of the cylinder.

Rotary crushers are commonly used to break down coal, limestone, and other similar materials in mining, quarrying, and construction industries. They are particularly useful for breaking down materials that are hard, brittle, or friable.

In addition to breaking down materials, rotary crushers can also be used to control the size and shape of the materials. By adjusting the size of the openings in the cylinder, operators can control the size of the final product.

Overall, rotary crushers are efficient and reliable machines that are commonly used in various industries for the purpose of breaking down and processing materials.

What are the common maintenance requirements for a rotary crusher?

Rotary crushers require regular maintenance to ensure they operate efficiently and safely. Here are some common maintenance requirements for rotary crushers:

Lubrication: Regular lubrication of the bearings, gears, and other moving parts of the rotary crusher is essential to prevent wear and tear and prolong the life of the machine.

Inspection of wear parts: The hammers or blades inside the cylinder of the rotary crusher are subject to wear and need to be regularly inspected and replaced as necessary.

Belt and chain tension: The belts or chains that drive the rotary crusher need to be regularly inspected and adjusted to ensure proper tension and prevent slippage.

Dust suppression: Dust and debris can build up inside the rotary crusher and cause problems, including decreased efficiency and potential safety hazards. Regular cleaning and dust suppression measures should be taken.

Electrical connections and control systems: Electrical connections and control systems need to be regularly inspected and maintained to prevent malfunctions and ensure safe operation.

Replacement of damaged parts: Any damaged parts, such as the cylinder or the bearings, need to be replaced promptly to prevent further damage to the machine.

Regular testing and calibration: Regular testing and calibration of the rotary crusher's components, such as the speed and torque sensors, can help detect any issues early and prevent breakdowns.

Overall, regular maintenance and inspection of a rotary crusher are essential to ensure safe, efficient, and reliable operation of the machine.

How to Install rotary crusher?

The installation process for a rotary crusher can vary depending on the specific model and manufacturer, but here are some general steps that may be involved in the installation process:

Site preparation: The site where the rotary crusher will be installed needs to be prepared. This may involve clearing the area, leveling the ground, and ensuring that the foundation is strong enough to support the weight of the machine.

Foundation construction: A strong and stable foundation is critical for the safe and effective operation of a rotary crusher. Depending on the specific model and manufacturer, the foundation may be made of concrete or steel. The foundation must be level and should be constructed according to the manufacturer's specifications.

Transport and positioning: The rotary crusher is typically delivered to the site in sections and needs to be assembled on site. The individual components of the machine are typically heavy and require specialized equipment to transport and position them.

Assembly: Once the individual components are in place, they need to be assembled according to the manufacturer's specifications. This may involve using bolts, welding, or other methods to connect the components.

Electrical and control system installation: The electrical and control systems for the rotary crusher need to be installed and connected to the power source. This may involve wiring the machine to a control panel or other control system.

Testing and commissioning: Once the rotary crusher is fully assembled and connected, it needs to be tested and commissioned to ensure that it is operating safely and efficiently. This may involve running the machine at various speeds and loads to ensure that it is performing according to the manufacturer's specifications.

Overall, the installation process for a rotary crusher requires specialized skills and equipment and should be performed by experienced professionals who are familiar with the specific model and manufacturer.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to