Industry Knowledge Extension

What safety precautions should be taken when operating a belt conveyor?

When operating a belt conveyor, it is important to take the following safety precautions to prevent accidents and ensure the safety of workers:

Proper training: All workers who operate, maintain, or repair belt conveyors should receive adequate training on the safe use of the equipment, including proper start-up and shut-down procedures, emergency stop procedures, and how to avoid getting caught in the machinery.

Guarding: All moving parts of the conveyor system should be guarded to prevent accidental contact by workers or objects. Guarding should be properly designed, installed and maintained.

Lockout/tagout procedures: Before any maintenance or repair work is done on the conveyor, it should be locked out and tagged out to prevent it from accidentally starting up.

Housekeeping: The area around the conveyor should be kept clean and free of clutter to prevent tripping hazards and to ensure that workers can move around the equipment safely.

Adequate lighting: Adequate lighting should be provided to ensure that workers can see clearly while working on or around the conveyor.

Personal protective equipment: Workers should wear appropriate personal protective equipment, such as safety glasses, hard hats, and safety shoes, when working on or near the conveyor.

Regular maintenance: Regular maintenance of the conveyor system should be performed to ensure that all parts are in good working order and to prevent breakdowns that could lead to accidents.

By following these safety precautions, workers can operate a belt conveyor safely and efficiently, while minimizing the risk of accidents and injuries.

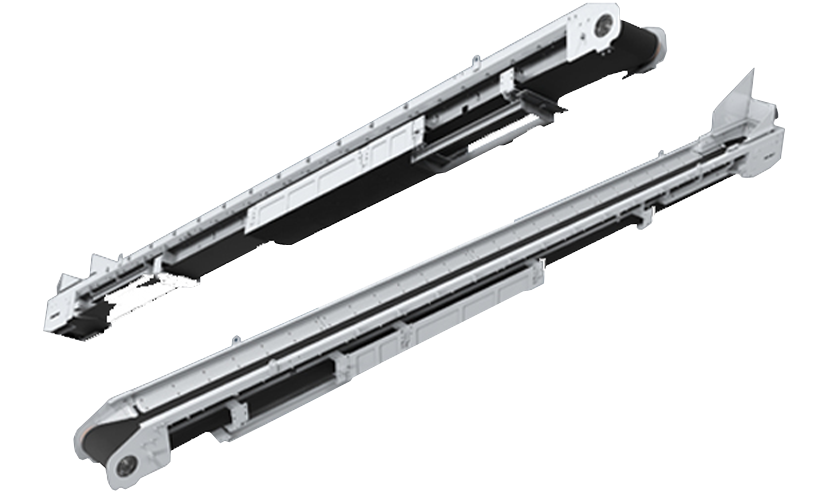

A belt conveyor is a type of material handling equipment that uses a continuous belt to transport objects or materials from one place to another. Belt conveyors are commonly used in industrial settings, such as manufacturing plants, warehouses, and distribution centers, to move goods along a production line or between different areas of a facility.

The basic components of a belt conveyor system include a belt, a driving unit that moves the belt, and support structures that hold the belt in place. The belt is typically made of a flexible material such as rubber, PVC, or polyester and is supported by rollers or other types of support structures.

Belt conveyors can be designed to move a wide range of materials, from lightweight products such as small parts and packages to heavy-duty materials such as coal and ore. They are available in a variety of configurations, including horizontal, inclined, and vertical orientations, and can be designed to operate at different speeds to meet specific application requirements.

Overall, belt conveyors are a reliable and efficient way to move materials and products within an industrial setting, and they play a critical role in many manufacturing and distribution operations.

What is a belt conveyor and how does it work?

A belt conveyor is a type of material handling equipment that uses a continuous belt to transport objects or materials from one location to another. It is a common conveyor system used in a variety of industries, including manufacturing, mining, and distribution.

The belt in a belt conveyor is typically made of a flexible material, such as rubber, PVC, or polyester. The belt is looped around a series of pulleys or rollers that support and guide the belt as it moves. A motor or other driving unit provides power to move the belt and the objects or materials it is carrying.

The basic operation of a belt conveyor is simple. The belt moves in a continuous loop, and objects or materials are placed on top of the belt at one end of the conveyor. As the belt moves, the objects are carried along with it to the other end of the conveyor, where they are deposited.

The speed at which the belt moves can be adjusted to control the flow rate of materials or objects. The orientation of the conveyor can also be adjusted, allowing it to move materials up an incline or around corners.

Overall, belt conveyors are a reliable and efficient way to move materials and products within an industrial setting. They can be customized to meet specific application requirements and are a critical component of many manufacturing and distribution operations.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский