Industry Knowledge Extension

What materials can the PFW European impact crusher handle?

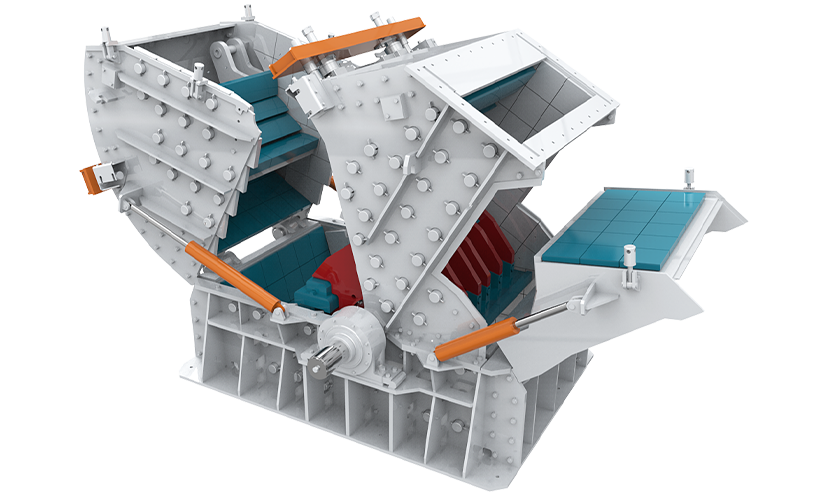

The PFW European impact crusher is a type of crushing machine designed to crush various materials. It is capable of handling materials with a size of up to 500mm and a compressive strength of up to 350MPa.

The materials that can be crushed by the PFW European impact crusher include:

Limestone

Dolomite

Gypsum

Coal

Shale

Sandstone

Quartzite

Granite

Basalt

Iron ore

In addition, the PFW European impact crusher can also be used to crush other materials such as construction waste, concrete, and asphalt. However, the specific materials that can be crushed may vary depending on the model and configuration of the crusher.

What safety features does the PFW European impact crusher have?

The PFW European impact crusher is designed with several safety features to ensure the safety of operators and maintenance personnel during operation. Some of the safety features include:

Hydraulic system: The PFW European impact crusher is equipped with a hydraulic system that allows for safe and easy adjustment of the crushing gap. This helps to prevent damage to the crusher and ensures consistent product quality.

Safety lock: The crusher is equipped with a safety lock that prevents the rotor from rotating when the top cover is open, preventing accidents and injury.

Rotor lock: The rotor lock prevents the rotor from moving when the apron is raised, providing a safe working environment for maintenance personnel.

Impact curtains: The impact curtains are located on both sides of the crusher and are designed to absorb the impact of material entering the crushing chamber. This helps to reduce wear on the crusher and ensures consistent product quality.

Emergency stop button: The crusher is equipped with an emergency stop button that can be activated in case of an emergency or malfunction, stopping the crusher immediately and preventing accidents.

Warning signs: The crusher is equipped with warning signs and labels that indicate the potential hazards associated with the operation and maintenance of the machine.

Overload protection: The crusher is equipped with an overload protection system that prevents damage to the crusher in case of overloading or tramp metal entering the crushing chamber.

Overall, the PFW European impact crusher is designed with several safety features to ensure the safe and efficient operation of the machine.

Regular maintenance and repair of the PFW European impact crusher are essential to ensure its optimal performance and longevity. Here are some tips on how to maintain and repair the PFW European impact crusher:

Regular inspection: Inspect the crusher regularly to ensure that all components are in good condition, including the rotor, impact plates, and liners.

Lubrication: Proper lubrication of the crusher is critical to its performance. Regularly lubricate the bearings, gears, and other moving parts to reduce friction and prevent wear.

Replace worn parts: Replace worn or damaged parts such as impact plates and liners promptly to prevent further damage to the crusher.

Tighten loose bolts: Check for loose bolts and tighten them to prevent vibration and damage to the crusher.

Clean the crusher: Keep the crusher clean of dirt and debris, and use compressed air to blow out any buildup of dust or debris.

Repair electrical components: If any electrical components are damaged, repair or replace them promptly to prevent safety hazards and malfunctions.

Hire a professional: For major repairs, it is recommended to hire a professional service technician who is trained to work on impact crushers to ensure the repair is done safely and properly.

Overall, regular maintenance and timely repairs are critical to keeping the PFW European impact crusher in optimal condition and extending its lifespan.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to