Industry Knowledge Extension

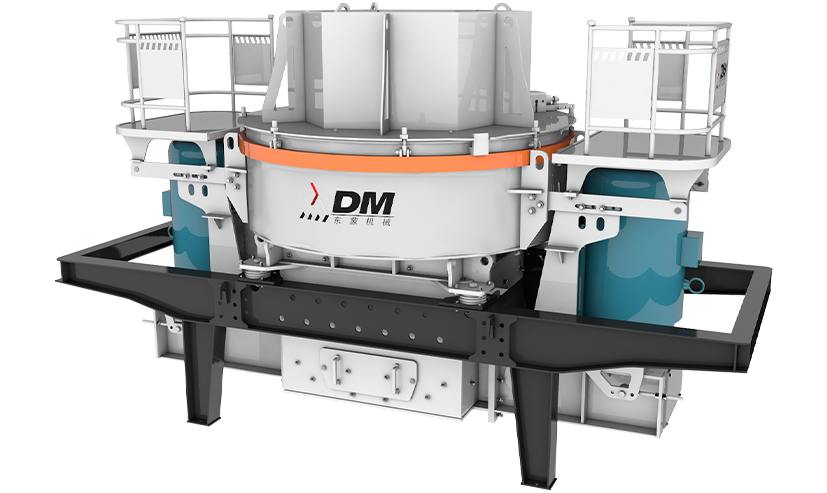

What is DVSI sand making machine?

DVSI sand making machine is a type of vertical shaft impact crusher, also known as vertical impact crusher or vertical shaft impact sand making machine. It is used to produce sand and stone materials for construction, highway, and other industries.

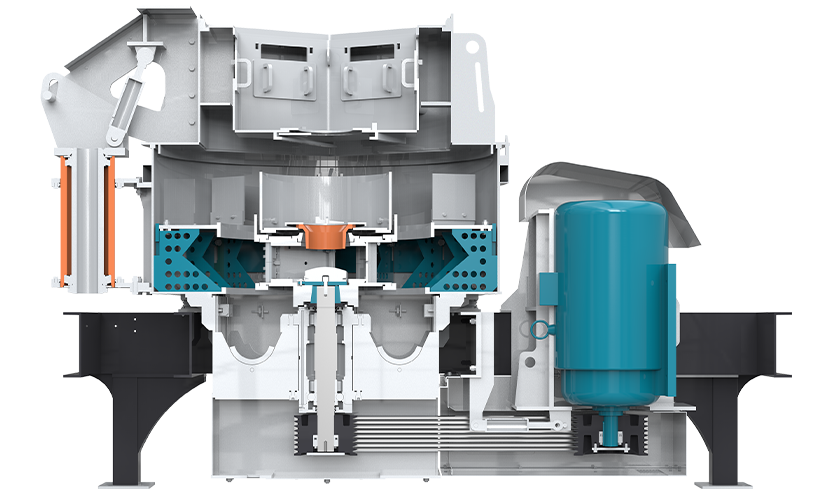

The machine is designed with a high-speed rotating impeller that throws materials into the crushing chamber, where they are crushed against the lining of the chamber by the impact of the impeller. The crushed materials are then discharged through the bottom of the machine.

The DVSI sand making machine is known for its high efficiency, low energy consumption, and low operating costs. It can produce high-quality sand and gravel materials with uniform particle size and good shape. The machine is widely used in the production of sand and stone materials in various industries, such as construction, mining, metallurgy, and chemical engineering.

There are several benefits of using DVSI sand making machine, including:

High efficiency: The machine uses a high-speed rotating impeller to crush materials, which ensures high crushing efficiency and production capacity.

Low operating costs: The machine consumes less energy and requires less maintenance compared to other sand making machines, resulting in lower operating costs.

Good particle shape: The machine produces sand and gravel materials with uniform particle size and good shape, which is ideal for use in construction projects.

Wide range of applications: The machine can be used to produce sand and stone materials for various industries, such as construction, mining, metallurgy, and chemical engineering.

Environmental friendliness: The machine is designed to reduce noise and dust pollution during operation, making it an environmentally friendly option.

High automation: The machine can be equipped with advanced control systems to achieve high automation and reduce labor costs.

Stable operation: The machine has a stable operation and low vibration, which ensures reliable performance and prolongs the service life of the equipment.

Overall, DVSI sand making machine is a cost-effective and efficient solution for producing high-quality sand and stone materials, making it a popular choice among various industries.

How to care and maintain DVSI sand making machine?

Proper care and maintenance of the DVSI sand making machine can help extend its service life, improve efficiency, and reduce operating costs. Here are some tips for caring and maintaining the machine:

Regularly check and maintain the lubrication system of the machine, including the oil level and quality, to ensure the machine operates smoothly.

Clean the machine regularly to remove any dust, dirt, or debris that may accumulate on the machine's surface and affect its performance.

Check the wear of the wearing parts, such as the impeller, lining plate, and bearing, and replace them in time to prevent further damage to the machine.

Adjust the tightness of the belt to ensure that it is not too loose or too tight, which can affect the operation of the machine.

Check the electrical system of the machine, including the wiring and control box, to ensure that it is working properly and safely.

Conduct regular inspections of the machine's bolts and fasteners, and tighten them if necessary to prevent any looseness that may cause the machine to malfunction.

Follow the manufacturer's recommended maintenance schedule and procedures, including replacing filters, cleaning air ducts, and checking the machine's overall performance.

By following these care and maintenance tips, you can ensure that your DVSI sand making machine operates efficiently, reliably, and for a long time.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to