Industry Knowledge Extension

Knowledge of Screw sand washer

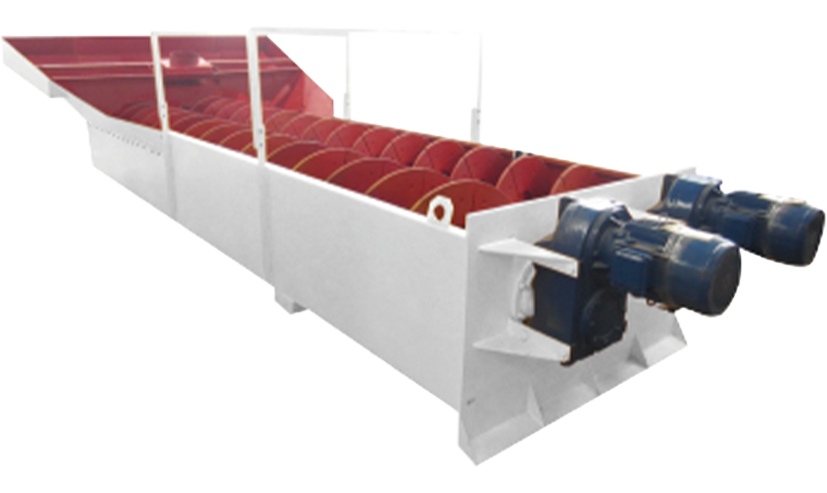

Screw sand washer is a type of sand washing machine used to clean and separate sand particles. It consists of a rotating screw shaft that moves the sand particles along the washer's trough and discharges them at the top. The water is pumped into the washer's trough to create a liquid bed, and the rotating screw lifts the sand particles from the bottom of the trough to the top.

The sand is then dewatered and discharged at the top of the washer. Screw sand washer is widely used in industries such as mining, construction, and sand processing plants. It is used to clean, classify, and dewater sand particles.

Screw sand washer has many advantages over traditional washing methods. It is efficient, economical, and requires less water compared to other washing methods. It can clean and dewater large volumes of sand in a short period of time. Additionally, it can remove impurities from sand particles and improve the sand quality.

However, screw sand washer requires regular maintenance and replacement of worn parts to ensure its optimal performance. The operator should check the washer's components regularly, such as the screw shaft, bearings, and sealing elements. Additionally, the operator should follow the manufacturer's guidelines for maintenance and operation to prevent equipment failure and extend the washer's lifespan.

The features of Screw sand washer can vary depending on the specific model and manufacturer. However, some common features of Screw sand washer include:

High efficiency: Screw sand washer can clean and separate sand particles efficiently, resulting in a high-quality output.

Large capacity: Screw sand washer can process large volumes of sand in a short period of time.

Low water consumption: Screw sand washer uses less water compared to traditional washing methods, making it more economical and environmentally friendly.

Durable construction: Screw sand washer is typically made of high-quality materials that can withstand harsh working conditions.

Easy maintenance: Screw sand washer is designed to be easy to maintain and repair, with readily available replacement parts.

Adjustable water discharge: Screw sand washer can adjust the amount of water used to create the liquid bed in the washer's trough, allowing for more precise cleaning and separation of sand particles.

Optional features: Some models of Screw sand washer may come with optional features, such as a vibrating screen to remove large debris or a fines recovery system to capture and recycle fine sand particles.

How Screw sand washer works

Screw sand washer works by using a rotating screw shaft to lift sand particles from the bottom of the washer's trough to the top, where they are discharged. The sand particles are mixed with water, creating a liquid bed in the trough. The screw rotates, pushing the sand particles and water mixture up the trough. As the mixture moves up the trough, the water drains out through small holes or slots, leaving behind the clean sand particles.

The operation of Screw sand washer can be broken down into several stages:

Loading: The sand and water mixture is fed into the washer's trough at one end.

Cleaning: As the mixture moves up the trough, the rotating screw lifts the sand particles and agitates them, removing impurities and dirt.

Dewatering: The water drains out of the trough through small holes or slots, leaving behind the clean sand particles.

Discharging: The clean sand particles are discharged from the top of the washer, while any remaining water or fine sand particles are discharged from the bottom.

The process of Screw sand washer can be repeated several times until the desired level of cleanliness and separation is achieved. The operation of Screw sand washer can be automated, with sensors and controls to regulate the flow of sand and water and adjust the speed of the screw shaft for optimal cleaning and dewatering.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский