Industry Knowledge Extension

What is PF impact crusher

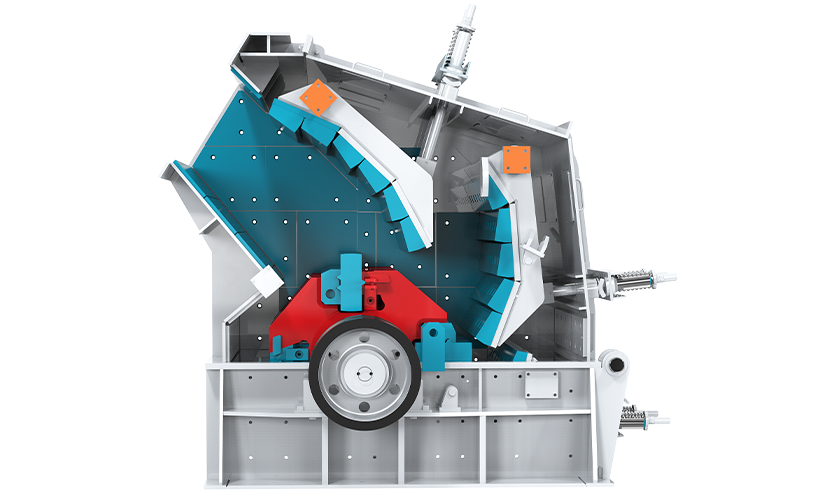

PF (PFW) impact crusher is a type of crusher that uses impact energy to crush materials. It is often used in the secondary or tertiary crushing stages in various fields such as mining, building materials, metallurgy, and chemical industries.

The PF impact crusher works by using a high-speed rotor that rotates horizontally, and the materials are fed into the crushing chamber through the feed opening. When the materials come into contact with the high-speed rotor, they are crushed by the impact force and are thrown back onto the impact plates on the rotor for further crushing. The crushed materials then exit through the discharge opening at the bottom of the crusher.

The PF impact crusher is known for its high efficiency, high reduction ratio, and low energy consumption. It also has the advantage of producing a cubical-shaped product, which is desirable for many applications. Additionally, it is easy to operate and maintain, making it a popular choice for many businesses.

The main functions of PF (PFW) impact crusher are:

Crushing: The primary function of the PF impact crusher is to crush materials with high-speed impact. It is used to crush materials with a compressive strength of up to 350 MPa, such as limestone, granite, and concrete.

Shaping: The impact crusher can produce a cubical-shaped product, which is desirable for many applications. The impact crusher achieves this by using a high-speed rotor and impact plates that break the materials into smaller pieces.

Secondary and Tertiary Crushing: The PF impact crusher is often used in the secondary and tertiary crushing stages. It is effective in producing a fine product size and reducing the size of the material to be further processed.

Low Energy Consumption: The PF impact crusher is designed to operate with low energy consumption. It uses less power compared to other crushers of the same size and capacity.

Easy Maintenance: The PF impact crusher is designed for easy maintenance, which makes it a popular choice for many businesses. It is easy to access the internal components, which simplifies the maintenance process.

Versatility: The PF impact crusher can be used in a variety of applications, including mining, construction, and demolition. It is capable of handling a wide range of materials, making it a versatile and valuable asset for many businesses.

What are the benefits of PF impact crusher?

Some of the benefits of PF (PFW) impact crusher are:

High Efficiency: The PF impact crusher is designed to operate with high efficiency. It uses a high-speed rotor and impact plates to break the materials into smaller pieces, resulting in a higher production rate and a more efficient operation.

High Reduction Ratio: The PF impact crusher is capable of producing a high reduction ratio. It can reduce the size of the material by up to 20:1, which is beneficial in many applications.

Low Energy Consumption: The PF impact crusher uses less power compared to other crushers of the same size and capacity, resulting in lower energy consumption and operating costs.

Cubical-Shaped Product: The PF impact crusher can produce a cubical-shaped product, which is desirable for many applications, such as the production of high-quality concrete and asphalt.

Easy Maintenance: The PF impact crusher is designed for easy maintenance. It is easy to access the internal components, which simplifies the maintenance process and reduces downtime.

Versatility: The PF impact crusher is capable of handling a wide range of materials, including soft to medium-hard rock, making it a versatile and valuable asset for many businesses.

Environmental Friendly: The PF impact crusher produces less dust and noise pollution compared to other crushers, making it a more environmentally friendly option.

Overall, the PF impact crusher is a reliable and efficient crushing machine that offers many benefits to businesses in various industries.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to