Industry Knowledge Extension

What is Mobile heavy screening station?

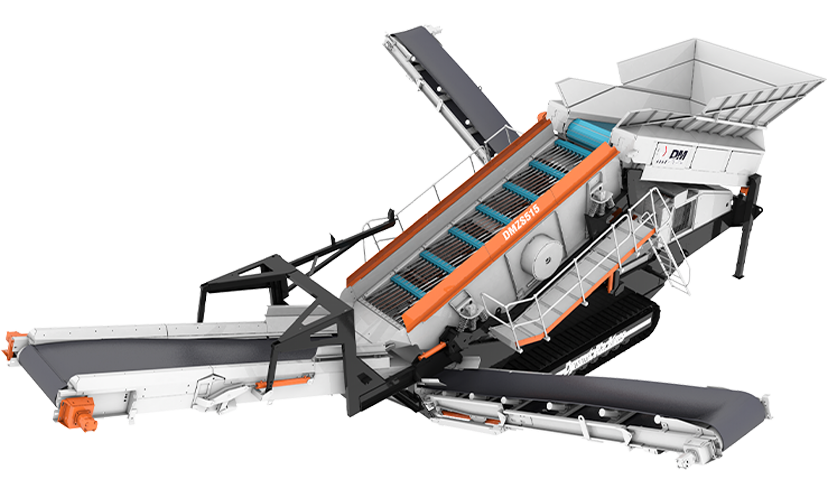

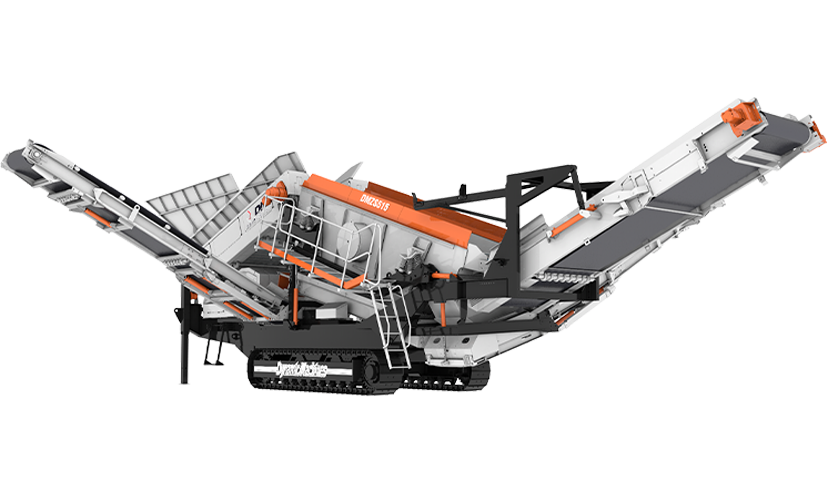

A mobile heavy screening station is a portable unit that is used to screen large volumes of material, such as soil, sand, gravel, or rock, for various applications. These units typically consist of a heavy-duty screening machine mounted on a trailer or truck bed, along with other equipment such as conveyors, feeders, and generators.

The screening machine itself usually consists of a large screening deck or drum, with various sizes of screens or meshes that allow different sized materials to be sorted and separated. The material is fed onto the screening deck or drum, and as it moves along, smaller materials fall through the screen while larger materials are carried along to the end of the machine.

Mobile heavy screening stations are commonly used in construction, mining, and landscaping applications, where large volumes of material need to be sorted or processed quickly and efficiently. They are also used in recycling operations to sort and separate different types of materials for further processing.

There are several types of mobile heavy screening stations available, each designed for different applications and materials. Here are some common types:

Trommel screens: These machines use a rotating drum to sort materials based on size. They are commonly used for processing soil, compost, and other organic materials.

Vibrating screens: These machines use vibrating screens to sort materials based on size. They are commonly used for processing sand, gravel, and other aggregates.

Scalping screens: These machines are designed to remove large, unwanted materials from a feed stream, such as rocks or debris. They are commonly used in mining and quarrying applications.

Flip-flow screens: These machines use a unique screening technology that allows them to sort materials that would typically clog or blind conventional screens, such as wet or sticky materials.

Star screens: These machines use rotating stars or discs to sort materials based on size. They are commonly used for processing compost and other organic materials.

Portable crushing and screening plants: These machines combine crushing and screening capabilities, allowing them to process large volumes of material in one operation. They are commonly used in construction and demolition applications.

The specific type of mobile heavy screening station used will depend on the application and the type of material being processed.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to