Industry Knowledge Extension

What is Mobile impact crushing station?

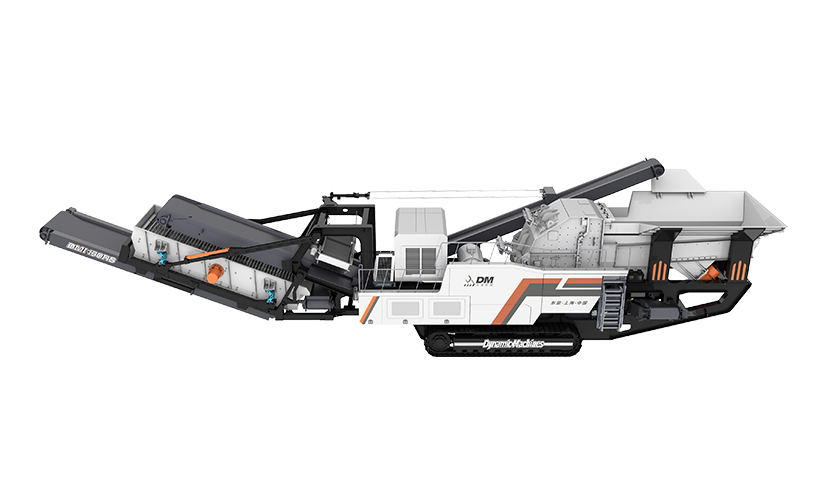

A mobile impact crushing station is a type of mobile crushing and screening plant that is designed to crush and screen various materials such as construction waste, rocks, and ores. It is a compact and flexible machine that can be easily transported to different worksites, making it ideal for construction, mining, and quarrying applications.

The mobile impact crushing station consists of a vibrating feeder, an impact crusher, a vibrating screen, a belt conveyor, and an electric control system. The materials are fed into the crusher by the vibrating feeder, and the impact crusher breaks them down into smaller sizes. The crushed materials are then screened by the vibrating screen to separate them into different sizes. The final products are transported by the belt conveyor to the designated location.

Mobile impact crushing stations are known for their high efficiency, low operating costs, and environmental friendliness. They are often used for crushing and recycling construction waste, which helps reduce the amount of waste that ends up in landfills. Additionally, they can also be used to process natural stones and ores for a variety of applications.

The Application of Mobile impact crushing station?

Mobile impact crushing stations have a wide range of applications in various industries. Some of the common applications of mobile impact crushing stations include:

Construction: Mobile impact crushing stations can be used for crushing and recycling construction waste, such as concrete, bricks, and asphalt. This helps to reduce the amount of waste that ends up in landfills and provides a cost-effective way of reusing these materials.

Mining: Mobile impact crushing stations can be used for processing various ores and minerals, including gold, silver, copper, and iron. They can be used as a primary or secondary crusher, depending on the application.

Quarrying: Mobile impact crushing stations can be used for quarrying natural stones, such as limestone, granite, and basalt. They can help to increase productivity and reduce the cost of transportation by allowing the processing of materials on-site.

Demolition: Mobile impact crushing stations can be used for demolition applications, such as breaking down buildings and structures. This helps to reduce the amount of waste that ends up in landfills and provides a cost-effective way of recycling materials.

Road construction: Mobile impact crushing stations can be used for processing materials for road construction, including asphalt and aggregates. They can be used to produce high-quality materials that meet the required specifications for road construction.

Overall, mobile impact crushing stations are a versatile and cost-effective solution for various crushing and screening applications.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to