Industry Knowledge Extension

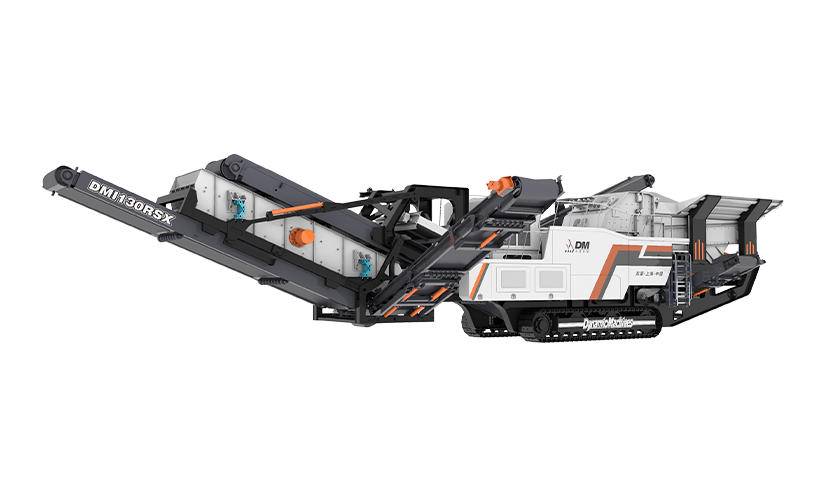

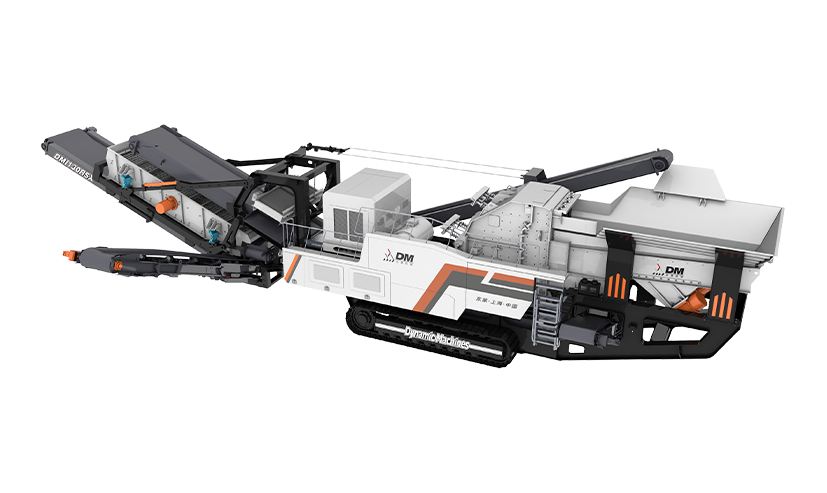

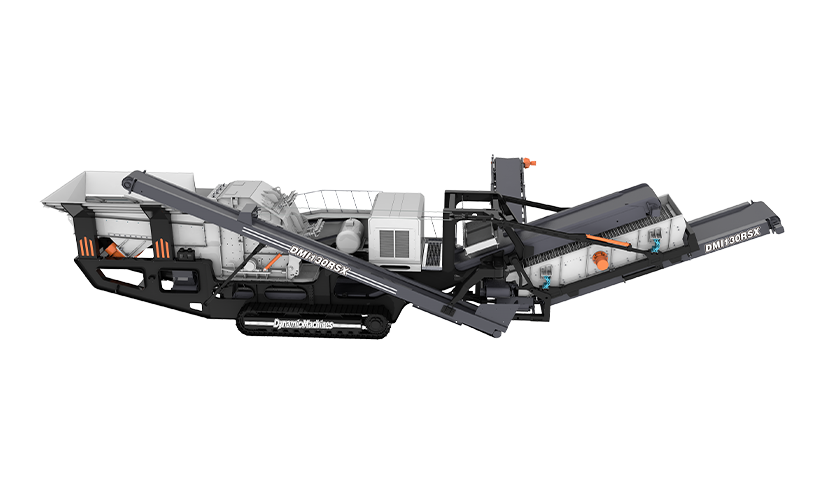

What is mobile all-in-one track crusher machine

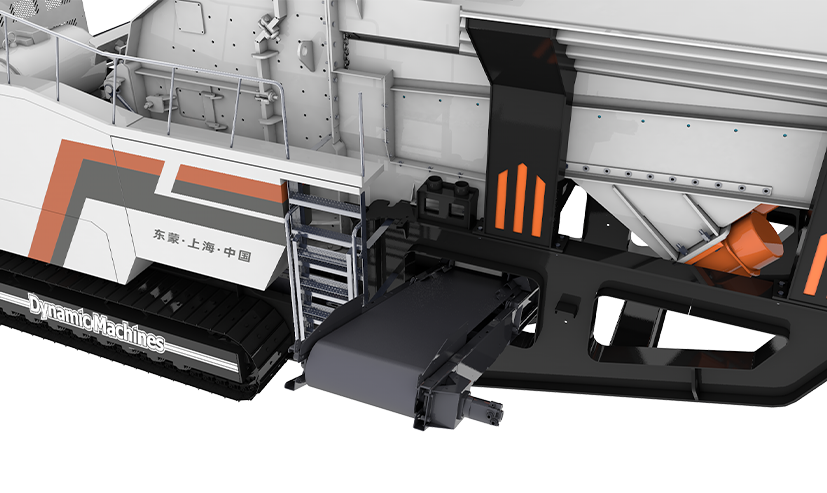

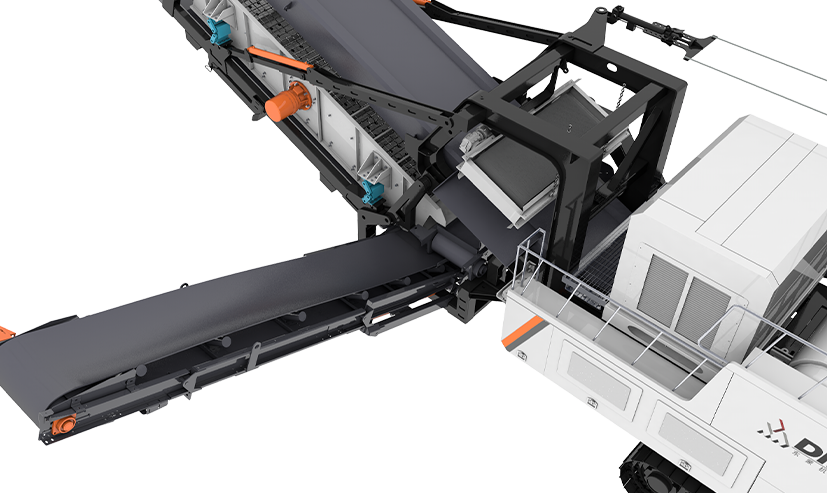

A "Mobile all-in-one Track Crusher" is a type of mobile crushing equipment that is designed to process and crush various materials such as rocks, concrete, and asphalt on-site. It is called "all-in-one" because it combines several functions into a single machine, including crushing, screening, and conveying.

The equipment consists of a mobile chassis with tracks that allow it to move over rough terrain and access hard-to-reach areas. The crushing unit is mounted on the chassis and can be moved to different locations as needed. The unit is powered by a diesel engine, which provides the necessary energy to run the crushing mechanism, as well as the tracks and other components.

The mobile all-in-one track crusher is commonly used in construction, mining, and demolition industries to process materials on-site, reducing the need for transportation and disposal of waste materials. It offers several benefits over traditional crushing equipment, including increased efficiency, flexibility, and reduced operating costs.

The features of a "Mobile all-in-one Track Crusher" may vary depending on the manufacturer and specific model. However, here are some common features that may be found on this type of mobile crushing equipment:

Crushing mechanism: The crushing unit of the machine typically consists of a jaw crusher, impact crusher, or cone crusher, depending on the intended use and materials to be processed. The mechanism is designed to crush various materials such as rocks, concrete, and asphalt into smaller sizes.

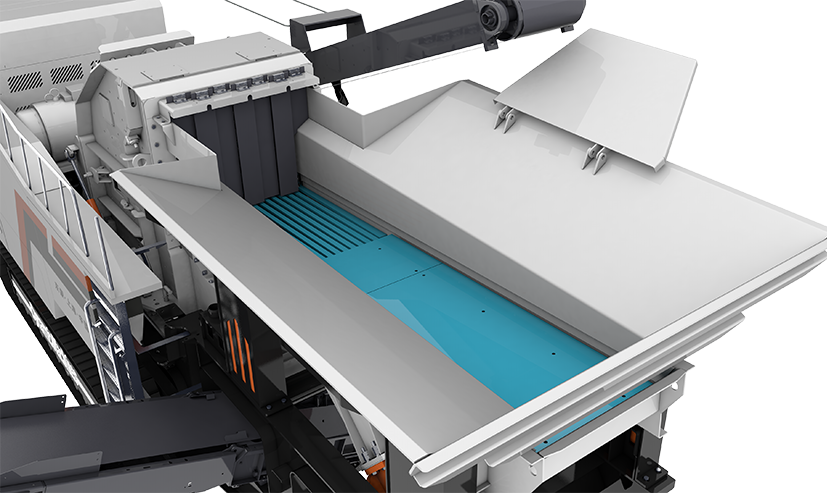

Screening mechanism: The machine may also have a screening mechanism that allows it to sort and classify the crushed materials based on size and other characteristics.

Conveying mechanism: The equipment may have a conveyor system that transports the crushed materials to a designated location or storage area.

Mobility: The machine is mounted on a mobile chassis with tracks that allow it to move over rough terrain and access hard-to-reach areas. This mobility feature makes it suitable for on-site processing of materials.

Diesel engine: The equipment is typically powered by a diesel engine, which provides the necessary energy to run the crushing mechanism, tracks, and other components.

Control system: The machine may have a control system that allows the operator to monitor and adjust various settings, such as speed, feed rate, and output size.

Safety features: The equipment may have several safety features, such as emergency shut-off switches, interlocks, and roll-over protection, to ensure safe operation.

Environmental features: The equipment may have features that help to reduce its environmental impact, such as emissions control systems and noise-reducing components.

Overall, the mobile all-in-one track crusher machine is designed to be a versatile, efficient, and mobile solution for on-site crushing and processing of various materials.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to