Industry Knowledge Extension

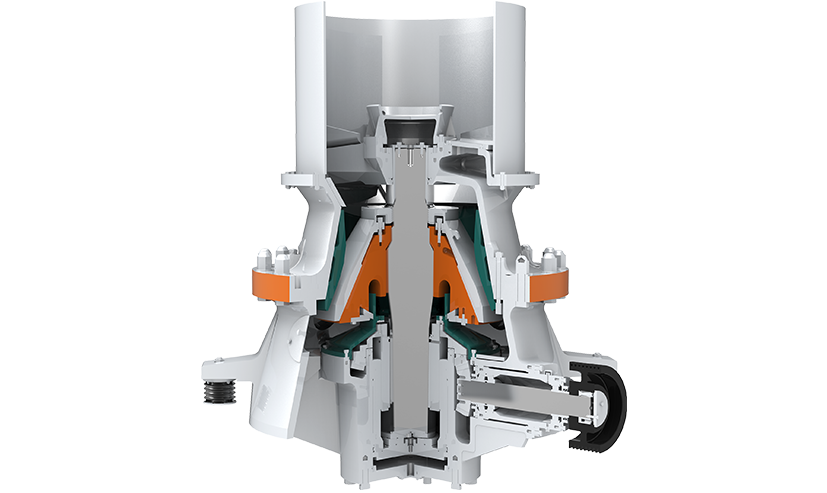

A single cylinder hydraulic cone crusher works by using a hydraulic cylinder to adjust the size of the discharge opening. The cylinder is located at the bottom of the crusher, and it is connected to the mainframe of the crusher through a piston rod. When the cylinder is pressurized, it moves the piston and the main shaft of the crusher up or down, which adjusts the size of the discharge opening.

The crushing process begins when the material enters the crushing chamber from the top, and it is fed into the crushing cavity through the feed opening. The material is then crushed by the fixed and movable cones, which are located in the crushing cavity. The fixed cone is stationary, while the movable cone moves back and forth to compress and crush the material.

The hydraulic cylinder controls the movement of the movable cone, and it adjusts the gap between the fixed and movable cones. This gap is called the crushing chamber, and it determines the size of the crushed material. The smaller the gap, the finer the crushed material.

Once the material is crushed to the desired size, it falls through the discharge opening at the bottom of the crusher. The hydraulic cylinder is then used to lift the movable cone back to its original position, ready for the next crushing cycle.

What are the advantages of using a single cylinder hydraulic cone crusher?

Here are some advantages of using a single cylinder hydraulic cone crusher:

High efficiency: Single cylinder hydraulic cone crushers use a single hydraulic cylinder to adjust the size of the discharge opening, which simplifies the process and increases the crushing efficiency.

Low operating cost: Single cylinder hydraulic cone crushers have a lower operating cost compared to other types of cone crushers because they have fewer moving parts and require less maintenance.

Easy maintenance: Single cylinder hydraulic cone crushers have a simple structure and are easy to maintain. The hydraulic cylinder can be easily accessed for maintenance, and the machine can be quickly disassembled for repair or replacement of parts.

Wide range of applications: Single cylinder hydraulic cone crushers can be used in a variety of applications, including mining, metallurgy, construction, and demolition.

High automation: Single cylinder hydraulic cone crushers can be equipped with advanced automation systems that allow operators to adjust the crusher settings remotely, monitor the machine's performance, and optimize the crushing process.

Uniform product size: Single cylinder hydraulic cone crushers produce a uniform product size, which is ideal for use in industries that require consistent product quality.

Overall, single cylinder hydraulic cone crushers offer a range of advantages that make them a popular choice for crushing applications in various industries.

What maintenance is required for a single cylinder hydraulic cone crusher?

Proper maintenance is essential for ensuring the smooth and efficient operation of a single cylinder hydraulic cone crusher. Here are some key maintenance tasks that should be performed regularly:

Regularly inspect the crusher's components for wear and tear, and replace any damaged or worn parts.

Check the oil level in the hydraulic system regularly, and top up as needed. It's important to use the recommended type and grade of hydraulic oil.

Check the oil temperature, pressure, and flow rate regularly, and make sure they are within the recommended range.

Clean the hydraulic system regularly to prevent contamination from dust, dirt, and debris.

Check the crusher's electrical system regularly, and replace any damaged or worn electrical components.

Lubricate the crusher's bearings and other moving parts regularly to prevent wear and tear.

Adjust the crusher's settings and parameters as needed to optimize its performance.

Inspect the crusher's safety devices regularly, and ensure that they are functioning properly.

Train operators on the proper operation and maintenance of the crusher, and ensure that they follow safety protocols and procedures.

Keep detailed records of the crusher's maintenance history, and use this information to develop a preventive maintenance plan.

Overall, regular maintenance is essential for keeping a single cylinder hydraulic cone crusher in good working condition and ensuring its longevity.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to