Industry Knowledge Extension

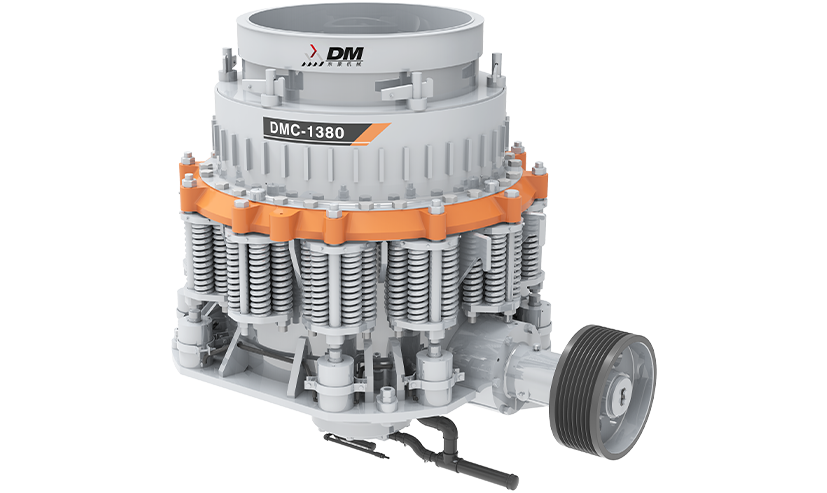

What is DMC Compound Cone Crusher and how does it work?

DMC Compound Cone Crusher is a type of cone crusher that is used for crushing various types of hard and abrasive materials. It is designed with advanced technology and engineering to provide high-quality crushing performance with low operating costs.

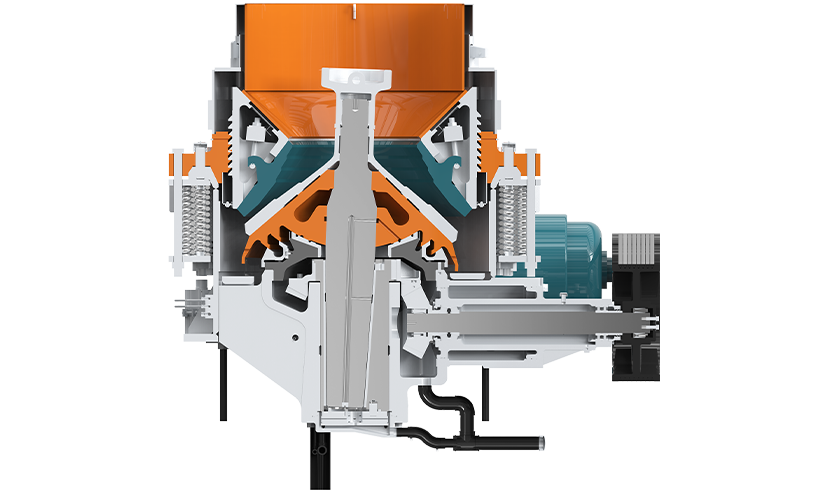

DMC Compound Cone Crusher works by using a rotating mantle and a stationary concave to crush rocks, ores, and other materials between them. The material enters the crusher through the top and is then compressed and crushed between the mantle and the concave. The crushed material is then discharged through the bottom of the crusher.

The unique design of DMC Compound Cone Crusher allows for efficient and effective crushing with minimal wear and tear on the machine. The machine also includes a hydraulic system that provides overload protection, ensuring that the crusher can operate safely and efficiently even when processing large amounts of material.

Overall, DMC Compound Cone Crusher is a reliable and efficient machine that is ideal for crushing a wide range of hard and abrasive materials, including granite, basalt, iron ore, and other minerals.

What are the main features and benefits of DMC Compound Cone Crusher?

The DMC Compound Cone Crusher offers several features and benefits that make it a reliable and efficient machine for crushing hard and abrasive materials. Some of these features and benefits include:

High crushing ratio: DMC Compound Cone Crusher has a high crushing ratio, which means that it can effectively crush materials with a large size reduction ratio.

Low operating costs: The machine has low operating costs due to its efficient design, which reduces energy consumption and maintenance costs.

Stable performance: DMC Compound Cone Crusher has stable performance, ensuring that the machine operates reliably and consistently, even when processing difficult materials.

Wide range of applications: The machine can be used to crush a wide range of hard and abrasive materials, including granite, basalt, iron ore, and other minerals.

Easy maintenance: The machine is designed for easy maintenance, with features such as easy access to wear parts and a hydraulic system that provides overload protection.

High automation level: The machine has a high level of automation, which reduces the need for manual intervention and helps to optimize the crushing process.

Environmental protection: The machine is designed to meet environmental protection standards, with features such as low noise and dust emissions.

Overall, the DMC Compound Cone Crusher is a reliable and efficient machine that offers several benefits for crushing hard and abrasive materials, making it ideal for a wide range of applications.

The Application of DMC Compound Cone Crusher

DMC Compound Cone Crusher is a versatile machine that can be used for a wide range of applications in various industries. Some of the common applications of DMC Compound Cone Crusher include:

Mining: The machine is widely used in mining operations for crushing hard and abrasive materials such as granite, basalt, iron ore, and other minerals.

Construction: DMC Compound Cone Crusher is also used in construction projects for crushing rocks, stones, and other construction materials.

Road construction: The machine can be used in road construction projects for crushing materials such as concrete and asphalt.

Aggregate production: DMC Compound Cone Crusher is used in aggregate production for crushing materials into smaller sizes for use in concrete, asphalt, and other construction applications.

Metallurgy: The machine is used in the metallurgy industry for crushing ores and other materials for processing.

Chemical industry: DMC Compound Cone Crusher can be used in the chemical industry for crushing and grinding various materials.

Overall, DMC Compound Cone Crusher is a versatile machine that can be used in various industries for crushing hard and abrasive materials. The machine's wide range of applications makes it an ideal choice for companies looking to invest in a reliable and efficient crushing solution.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to