Industry Knowledge Extension

The main components of a multi-cylinder hydraulic cone crusher typically include:

Main frame: The main frame is a heavy-duty steel structure that provides support and stability for the crusher.

Adjustment ring: The adjustment ring is used to adjust the size of the discharge opening of the crusher.

Bowl: The bowl is the stationary component of the crusher where the material is crushed by the mantle.

Mantle: The mantle is the moving component of the crusher that crushes the material against the bowl.

Eccentric assembly: The eccentric assembly includes the main shaft, eccentric shaft, and counterweight. It is used to rotate the mantle and bowl.

Hydraulic system: The hydraulic system is used to adjust the size of the discharge opening and to protect the crusher from damage caused by tramp materials.

Drive motor: The drive motor is used to power the crusher.

Feed hopper: The feed hopper is the opening through which the material is fed into the crusher.

Discharge chute: The discharge chute is used to direct the crushed material to a conveyor or other processing equipment.

Lubrication system: The lubrication system is used to lubricate the bearings and other moving parts of the crusher to reduce wear and prevent damage.

How do you maintain a multi-cylinder hydraulic cone crusher?

Regular maintenance is essential to keep a multi-cylinder hydraulic cone crusher running smoothly and to prevent breakdowns. Here are some general tips for maintaining a multi-cylinder hydraulic cone crusher:

Check the oil level and quality regularly: Check the oil level and quality of the lubrication system, including the oil tank, oil filter, oil pump, and oil pressure gauge. Replace the oil and filter regularly according to the manufacturer's recommendations.

Inspect the hydraulic system: Check the hydraulic system for leaks, damaged hoses, and loose fittings. Make sure the hydraulic pressure is set to the correct level.

Inspect the crusher liners: Inspect the crusher liners for wear and replace them if necessary. This will help prevent damage to the crusher's internal components.

Check the crusher settings: Check the crusher settings regularly to ensure that they are set to the correct specifications for the material being crushed.

Inspect the crusher components: Inspect the crusher components, such as the eccentric assembly, bowl, and mantle, for wear and damage. Replace any components that are worn or damaged.

Keep the crusher clean: Clean the crusher regularly to prevent build-up of dirt, dust, and debris. This will help prevent damage to the crusher's internal components and ensure smooth operation.

Train operators and maintenance staff: Provide training to operators and maintenance staff on how to properly operate and maintain the crusher.

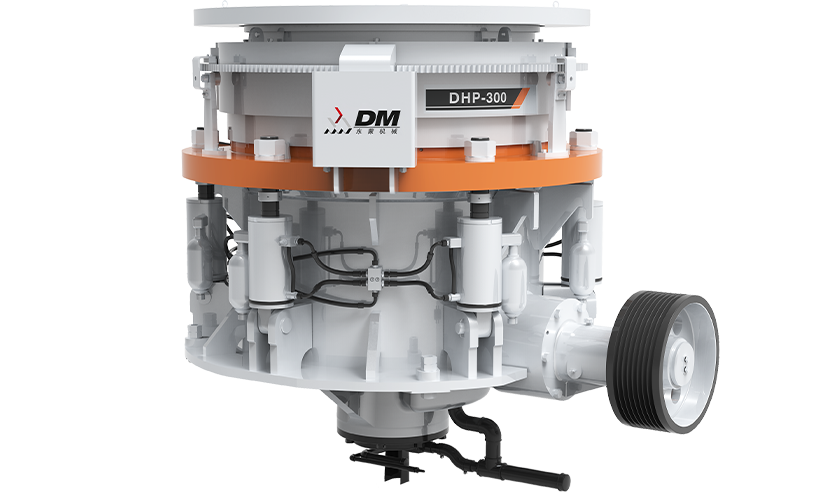

The DHP multi-cylinder hydraulic cone crusher features a number of advanced technologies, including a multi-point hydraulic lubrication system, a hydraulic overload protection system, and a high-performance crushing chamber design. It is available in a range of sizes and configurations to meet the specific needs of different crushing applications.

Some of the key features of the DHP multi-cylinder hydraulic cone crusher include high crushing efficiency, low operating costs, easy maintenance, and a long service life. It is suitable for crushing a wide range of materials, including hard and medium-hard rocks, ores, and minerals.

Overall, the DHP multi-cylinder hydraulic cone crusher is a reliable and efficient crushing solution that can help improve the productivity and profitability of mining and quarrying operations.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to