Industry Knowledge Extension

What are the advantages of using a mobile jaw crushing station compared to other types of crushers?

There are several advantages of using a mobile jaw crushing station compared to other types of crushers, including:

Flexibility and mobility: A mobile jaw crushing station is designed to be easily transported between different worksites, which makes it ideal for use in construction projects, mining operations, and other settings where the crushing equipment needs to be moved frequently.

Higher efficiency: Mobile jaw crushers are designed to crush materials on-site, which reduces the need for transportation of materials to a stationary crusher. This can lead to higher efficiency and lower operating costs.

Versatility: Mobile jaw crushers can be used to crush a wide range of materials, including concrete, asphalt, and brick, as well as natural rock. They can also handle a variety of sizes and shapes of materials, which makes them versatile in many different applications.

Reduced environmental impact: By crushing materials on-site, mobile jaw crushing stations can reduce the amount of waste and debris that needs to be transported and disposed of. This can help to reduce the environmental impact of construction and demolition projects.

Improved safety: Mobile jaw crushing stations are designed with safety in mind, with features such as remote control operation and safety guards to help prevent accidents and injuries.

Overall, the mobility, versatility, and efficiency of mobile jaw crushing stations make them a popular choice for many different industries and applications.

What types of materials can be processed using a mobile jaw crushing station?

Mobile jaw crushing stations are designed to crush a wide range of materials, including:

Natural rock: Mobile jaw crushing stations are well-suited for processing natural rock, such as granite, limestone, and basalt.

Construction and demolition waste: Mobile jaw crushing stations can be used to crush and recycle construction and demolition waste, including concrete, asphalt, brick, and other materials.

Quarry waste: Mobile jaw crushing stations can also be used to process quarry waste, including overburden, blasted rock, and other materials.

Ores: Mobile jaw crushing stations can be used to process various ores, including gold, silver, copper, and iron.

Industrial minerals: Mobile jaw crushing stations can also be used to process industrial minerals, including phosphate, potash, and salt.

The specific materials that can be processed using a mobile jaw crushing station will depend on the design of the crusher and the size and hardness of the materials being crushed. It's important to consult with a manufacturer or supplier to determine if a particular mobile jaw crushing station is appropriate for a specific application or project.

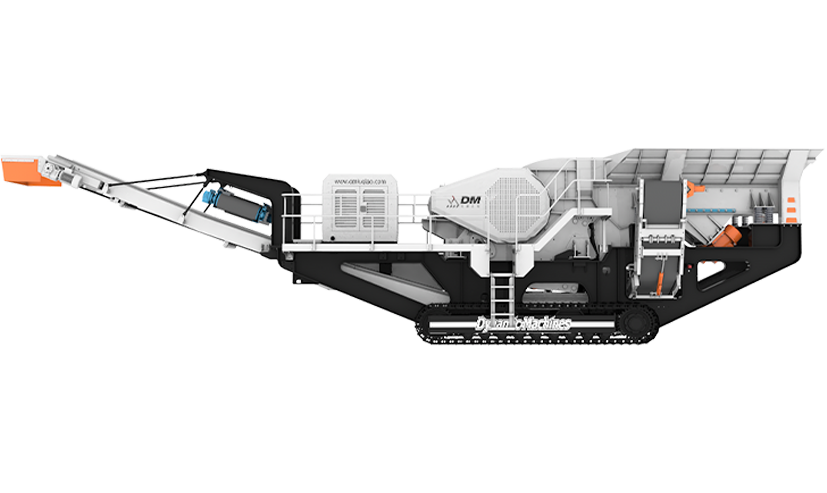

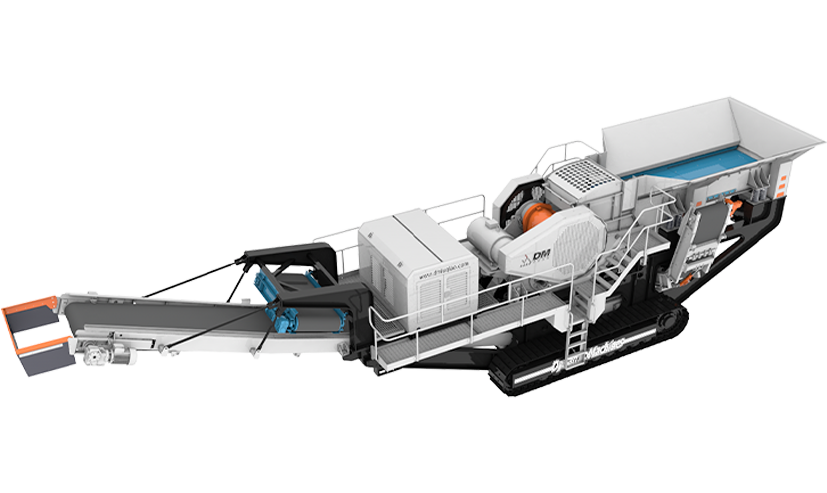

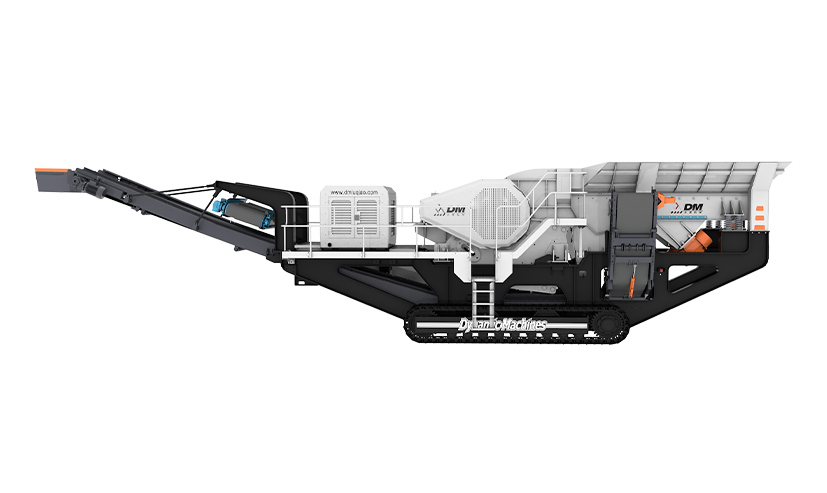

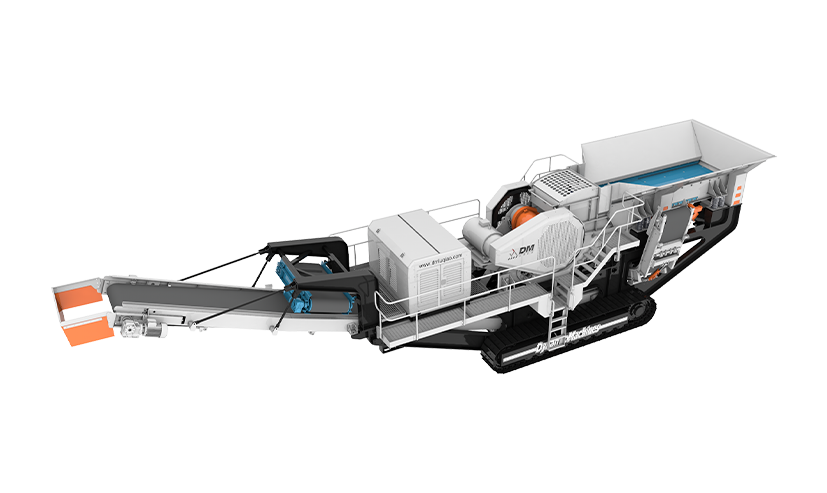

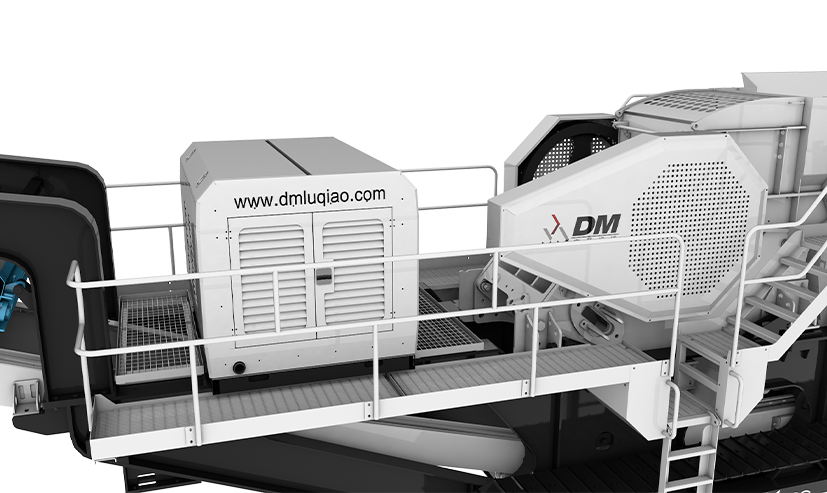

What is mobile jaw crushing station?

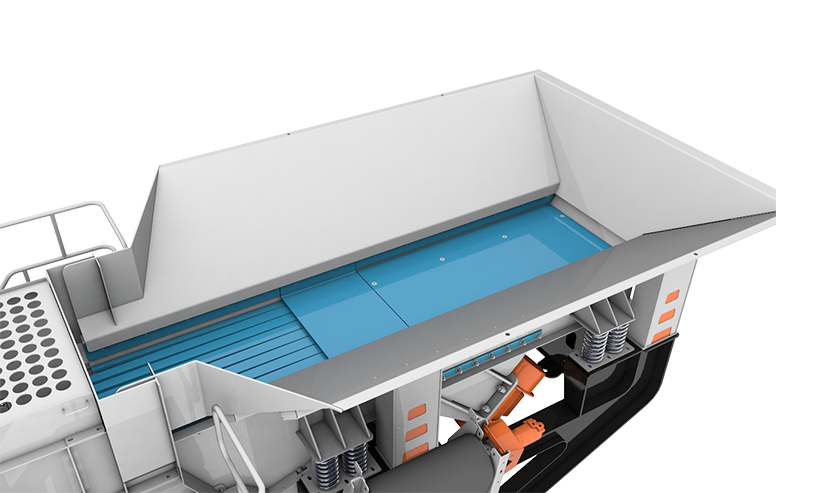

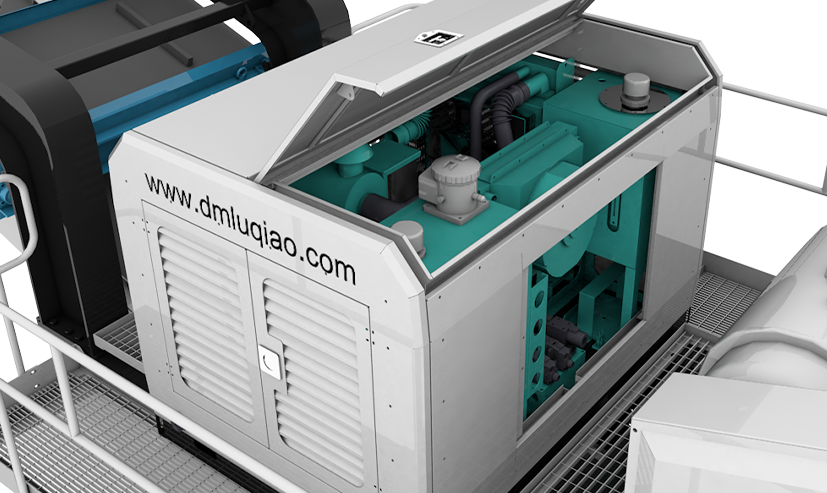

A mobile jaw crushing station is a type of mobile crushing and screening plant that is designed to process large rocks and other materials into smaller pieces, using a primary jaw crusher. The mobile jaw crusher is mounted on a crawler chassis that can be easily transported from one work site to another.

The mobile jaw crushing station is typically used in industries such as mining, metallurgy, building materials, and construction waste recycling. It is designed to crush a wide range of materials, including natural rock, concrete, asphalt, and other materials.

Mobile jaw crushing stations are highly flexible and adaptable, allowing them to be used in a variety of different applications. They can be equipped with additional features such as a vibrating feeder, a pre-screening unit, and a conveyor belt to optimize the crushing process and improve overall efficiency.

The advantages of a mobile jaw crushing station include its mobility, versatility, and ability to reduce the need for transport of materials to a stationary crusher. Additionally, a mobile jaw crushing station is often safer and more cost-effective than traditional crushing methods, making it a popular choice for a wide range of applications.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to