Industry Knowledge Extension

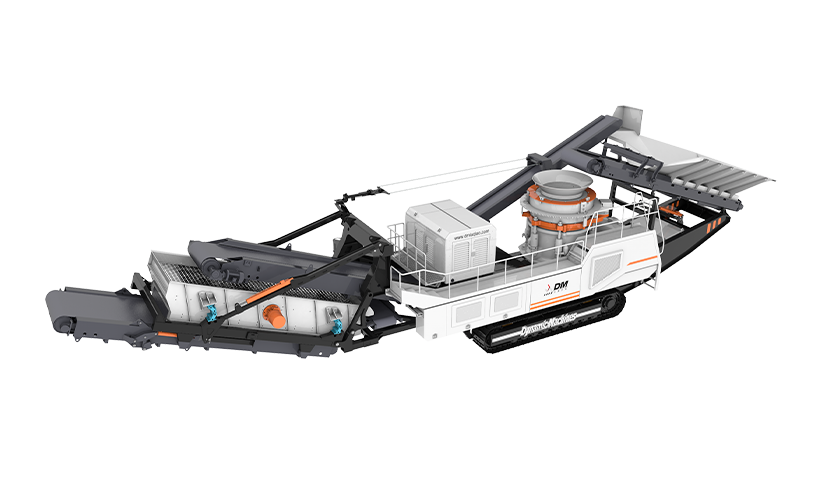

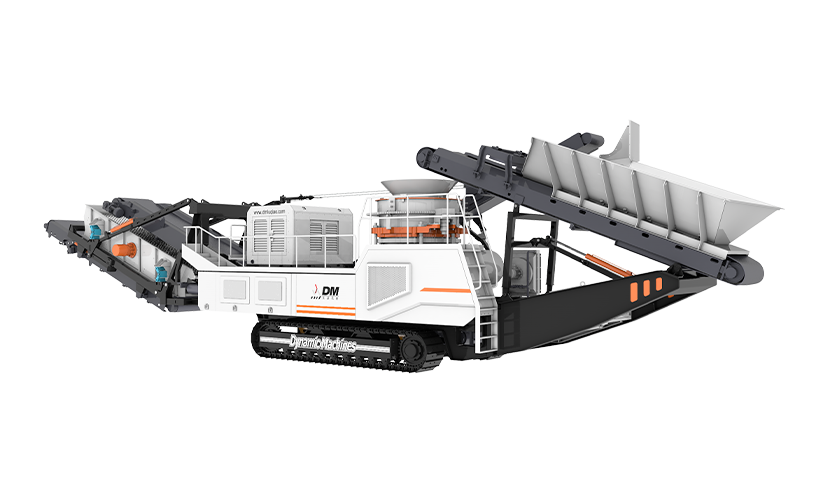

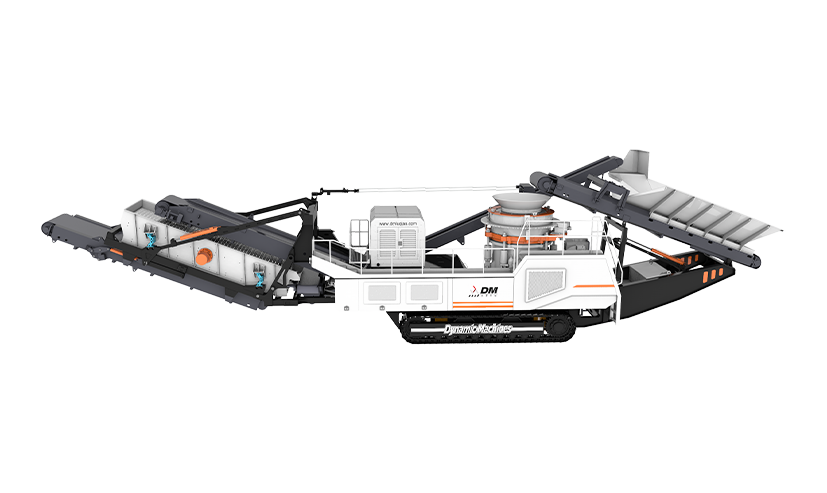

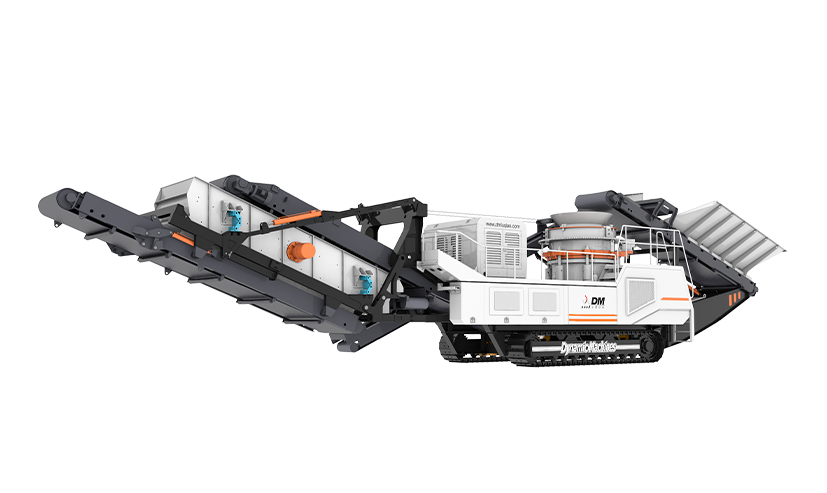

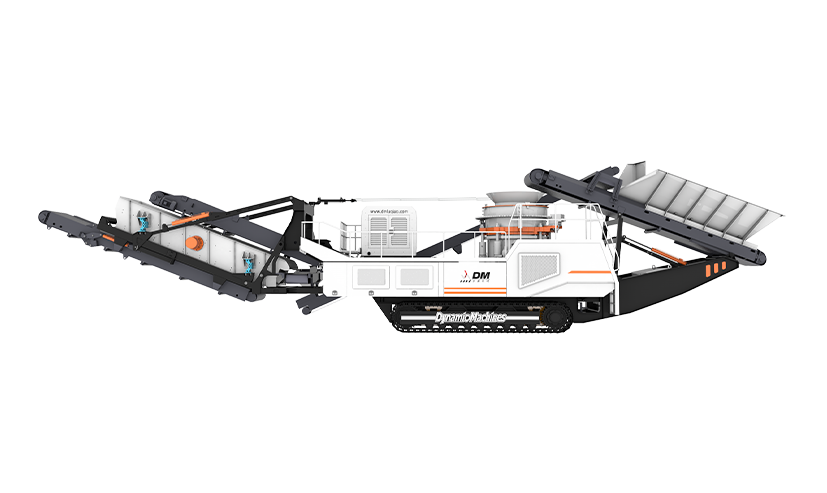

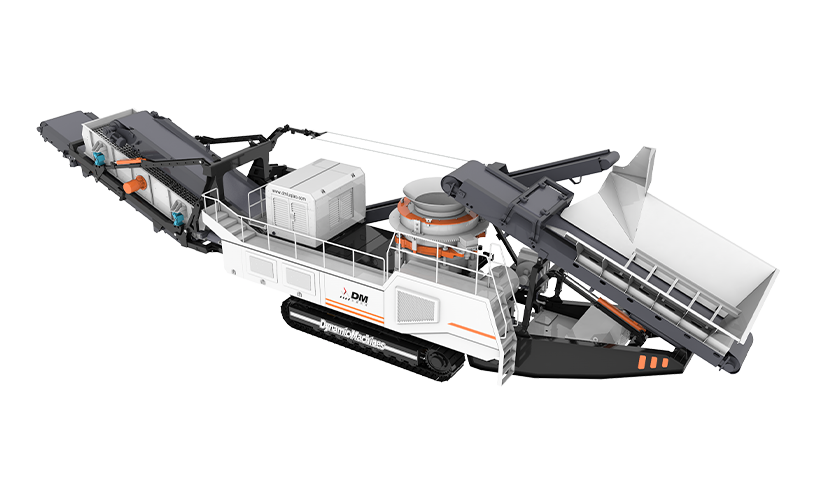

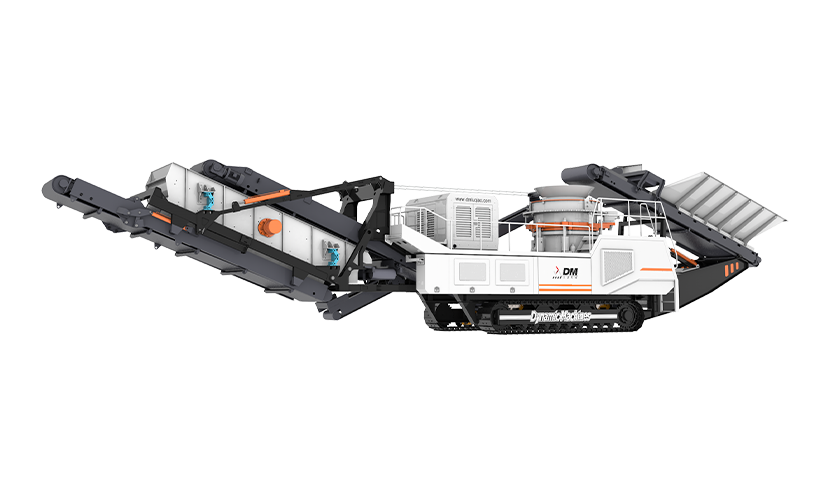

Mobile cone crushing station is a type of portable crushing plant that is designed to be moved easily from one location to another. It is composed of a cone crusher, vibrating screen, belt conveyor, and control cabinet. The mobile cone crusher is designed for secondary and tertiary crushing applications, where the material is fed into the cone crusher and crushed by the crushing chamber's rotating mantle.

The vibrating screen separates the crushed material into different sizes, and the belt conveyor moves the material to the designated location. The control cabinet houses the control panel for the entire crushing plant and is used to monitor and control the operation of the mobile cone crusher.

Mobile cone crushing stations are commonly used in mining, quarrying, and construction industries, where they provide an efficient and cost-effective solution for crushing and screening operations. They are particularly useful for processing hard and abrasive materials, such as granite, basalt, and limestone, as well as for recycling concrete and asphalt.

What are the benefits of Mobile cone crushing station?

Mobile cone crushing stations offer several benefits over traditional stationary crushing plants, including:

Mobility: The main advantage of a mobile cone crushing station is its ability to be moved easily from one location to another. This makes it an ideal solution for on-site crushing and screening operations, reducing the need for expensive transportation and logistics.

Flexibility: Mobile cone crushing stations are designed to be adaptable to various crushing applications, including both hard and soft rocks, as well as different material types and sizes.

Efficiency: With a mobile cone crushing station, the material can be processed right where it is extracted, reducing the need for expensive transport and reducing processing time. This can lead to increased efficiency and productivity.

Cost-effective: Mobile cone crushing stations can be more cost-effective than traditional stationary plants, as they do not require as much infrastructure, such as foundations and buildings, and can be powered by diesel generators, reducing the need for a permanent power supply.

Environmental benefits: Mobile cone crushing stations are designed to be environmentally friendly, with features such as low emissions engines, dust suppression systems, and noise reduction technology. This can help reduce the impact of crushing operations on the environment and nearby communities.

Overall, mobile cone crushing stations offer a versatile, efficient, and cost-effective solution for on-site crushing and screening operations, making them an ideal choice for many industries.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский

Drag the picture left or right to

Drag the picture left or right to