Industry Knowledge Extension

What is suspended small plate feeder?

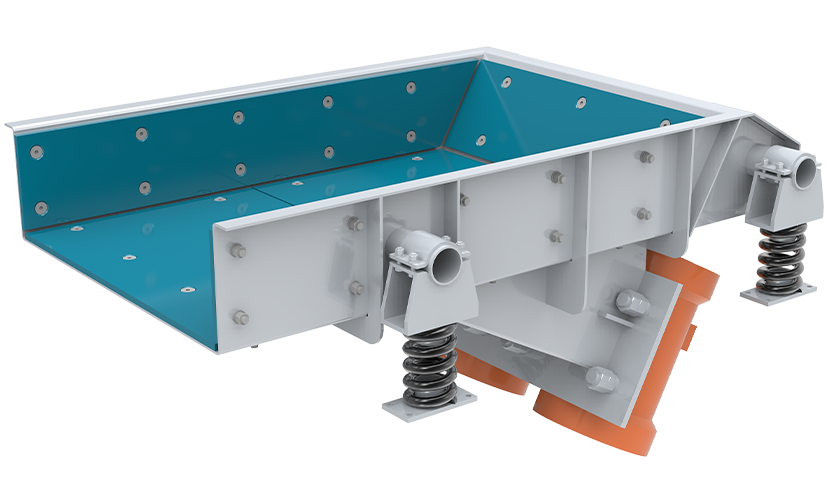

A suspended small plate feeder is a type of feeding equipment used in material handling systems. It consists of a small plate conveyor suspended from a beam or bridge structure, which is designed to transport small-sized materials from one location to another.

The small plate feeder operates by using a series of small plates that are attached to a chain or belt, which moves along the conveyor. The plates are designed to carry small-sized materials such as powders, granules, and small particles.

The feeder is suspended from a beam or bridge structure using cables or chains, which allows it to move along the structure and transport materials to different locations. The suspended design of the feeder provides several benefits, such as reduced noise and vibration, increased stability, and improved flexibility in material handling.

Suspended small plate feeders are commonly used in industries such as mining, cement, and chemical processing, where small-sized materials need to be transported efficiently and reliably. They are often used in combination with other material handling equipment, such as hoppers, silos, and crushers, to create a complete material handling system.

Proper care and maintenance of a suspended small plate feeder can help ensure optimal performance, extend its lifespan, and prevent breakdowns. Here are some tips for caring and maintaining suspended small plate feeders:

Regular Cleaning: The feeder should be regularly cleaned to prevent the accumulation of material on the plates or conveyor belt, which can lead to clogging and damage to the equipment. Use a soft brush or compressed air to remove any dust or debris from the feeder.

Lubrication: The moving parts of the feeder, such as the conveyor chain or belt, should be lubricated regularly to prevent wear and tear. Use the manufacturer's recommended lubricant and apply it to the moving parts as per the instructions.

Inspection: The feeder should be inspected regularly to check for any signs of wear or damage, such as cracks, corrosion, or loose bolts. Any damaged parts should be repaired or replaced immediately to prevent further damage to the equipment.

Alignment: The feeder should be checked for proper alignment, as misalignment can cause wear and tear on the moving parts and affect the overall performance of the feeder. Adjust the alignment as per the manufacturer's instructions.

Proper Use: The feeder should be used only as per the manufacturer's instructions and within its design limits. Overloading or using the feeder for materials that it is not designed for can cause damage to the equipment.

Training: Ensure that the operators and maintenance personnel are properly trained on the use and maintenance of the feeder to prevent any mistakes or accidents.

By following these care and maintenance tips, you can ensure that your suspended small plate feeder is operating efficiently and reliably, leading to increased productivity and reduced downtime.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский