Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

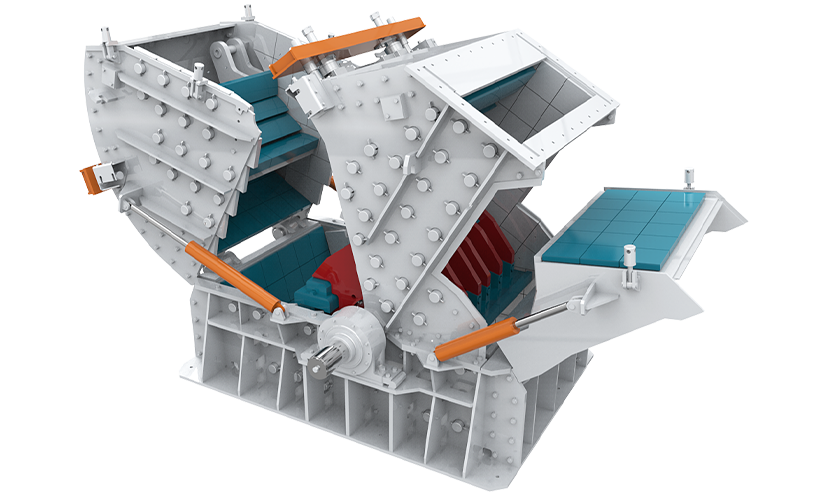

The Impact Hammer Crusher Factory, known for its robust design and efficient operation, is a critical component in the mining and quarrying industry. As technology advances, the focus on energy efficiency in factories has become more pronounced, especially concerning the operation of heavy machinery like impact hammer crushers. This article will explore the energy consumption patterns within the Impact Hammer Crusher Factory and evaluate the measures taken to optimize these processes.

The Impact Hammer Crusher Factory is designed to handle a wide range of materials, from coal to limestone, with the primary goal of reducing the size of feed material to manageable pieces. The energy consumption of these factories is a significant factor in their overall operational costs and environmental impact. To understand the energy consumption in the Impact Hammer Crusher Factory, we must consider the various stages of the crushing process.

During the initial stage of operation, the Impact Hammer Crusher Factory requires a substantial amount of energy to initiate the crushing process. The electric motors or diesel engines used to power the crushers consume a notable amount of energy to bring the machinery to operational speed. Once the crusher reaches its suitable speed, the energy consumption decreases slightly but remains high due to the continuous force exerted by the hammers on the materials.

The energy consumption in the Impact Hammer Crusher Factory is also influenced by the type and hardness of the material being crushed. Harder materials require more energy to break down, which directly impacts operational costs. Additionally, the size of the feed material and the desired output size play a crucial role in determining the energy requirements. Larger feed material and smaller output sizes demand more energy, as the crushing process becomes more laborious.

To reduce energy consumption in the Impact Hammer Crusher Factory, manufacturers have been investing in research and development to improve the design and efficiency of the crushers. Modern impact hammer crushers are equipped with advanced technology that allows them to operate at suitable efficiency, thereby reducing energy waste. For instance, variable speed drives and intelligent control systems can adjust the speed and force of the crushers based on the material being processed, causing significant energy savings.

Another approach to reducing energy consumption in the Impact Hammer Crusher Factory is through the implementation of energy recovery systems. These systems capture and reuse the energy generated during the crushing process, which can be redirected back into the factory's power supply. This not only reduces the overall energy consumption but also contributes to a more sustainable operation.

Regular maintenance and proper operation of impact hammer crushers are also crucial in managing energy consumption. Well-maintained crushers operate more efficiently, reducing wear and tear and reducing energy waste. Additionally, operators should be trained to monitor the performance of the crushers and make adjustments as needed to optimize energy use.

In conclusion, the energy consumption in the Impact Hammer Crusher Factory is a multifaceted issue that requires a comprehensive approach to address. By investing in advanced technology, implementing energy recovery systems, and focusing on proper maintenance and operation, these factories can significantly reduce their energy consumption. As the demand for sustainable and energy-efficient operations grows, the role of the Impact Hammer Crusher Factory in meeting these challenges becomes increasingly important. The future of these factories lies in their ability to adapt and innovate, ensuring that they remain at the forefront of the mining and quarrying industry while minimizing their environmental footprint.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!