Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

Cone crushers are widely used in mining, quarrying, and aggregate production for secondary and tertiary crushing. However, varying operational conditions can cause overload, which negatively impacts efficiency, component wear, and machine longevity. A Cone Crusher Factory must consider feed characteristics, machine settings, and operational management to decrease overload risks. Understanding how different factors contribute to overload is crucial for maintaining stable production and prolonging the crusher’s service life.

1. Feed Material Characteristics

Hardness and Abrasiveness: Harder or highly abrasive materials require greater crushing force, increasing the risk of overload.

Moisture Content: Wet or sticky materials may clump together, causing uneven feeding and excessive load on the crusher.

Feed Size and Uniformity: Oversized feed particles or inconsistent feed distribution can exceed the crusher’s capacity.

2. Operational Settings

Eccentric Speed and Stroke: High eccentric speeds or large strokes increase crushing force, which can cause overload if feed conditions are not optimal.

Closed-Side Setting (CSS): Incorrect CSS settings may force the crusher to process more material than it can handle efficiently.

Motor Power and Torque Limits: Exceeding the designed torque can trigger protective shutdowns or cause mechanical stress on components.

1. High Production Demand

During peak production, feeding rates may surpass design capacity.

Continuous overloading under these conditions causes increased wear on liners and bearings.

2. Variable Feed Quality

Mixed feed containing both soft and extremely hard rocks may cause sudden spikes in load.

Soft particles may pass easily, while hard fragments can momentarily overload the crushing chamber.

3. Uncontrolled Moisture or Sticky Materials

Wet materials tend to stick and bridge within the crushing chamber.

This sudden resistance can cause short-term overload and trigger the crusher’s protection system.

1. Hydraulic Protection Systems

Modern cone crushers include hydraulic relief systems that automatically adjust the crusher to prevent overload.

This system allows uncrushable material to pass through without damaging the equipment.

2. Robust Component Design

Liners, mantle, and bowl are made from wear-resistant materials capable of withstanding sudden load spikes.

Reinforced bearings and frame structure reduce the risk of mechanical failure during overload conditions.

3. Adjustable Operational Parameters

Variable eccentric speeds and CSS adjustments enable operators to fine-tune the crusher according to feed conditions.

Adaptive settings maintain production while reducing stress on the machine.

1. Consistent Feed Management

Pre-screening oversized rocks and controlling feed rate prevents sudden surges.

Uniform feed distribution ensures the crusher operates within its design limits.

2. Monitoring and Automation

Sensors and real-time monitoring systems track load, torque, and vibration.

Automatic adjustments or alerts prevent prolonged overload situations.

3. Maintenance and Inspection

Regular inspection of wear parts and lubrication reduces the likelihood of component failure under high load.

Proactive replacement of worn liners and bearings ensures the crusher can handle the designed capacity without overload.

Cone crushers may experience overload under various conditions, including uneven feed, high hardness, or high production demand. A Cone Crusher Factory addresses these challenges through hydraulic protection, robust design, adjustable operational settings, and automated monitoring. Proper feed management, maintenance, and parameter optimization help maintain efficiency while reducing overload risk. By integrating these strategies, operators can ensure reliable, safe, and efficient performance even under demanding operating conditions.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

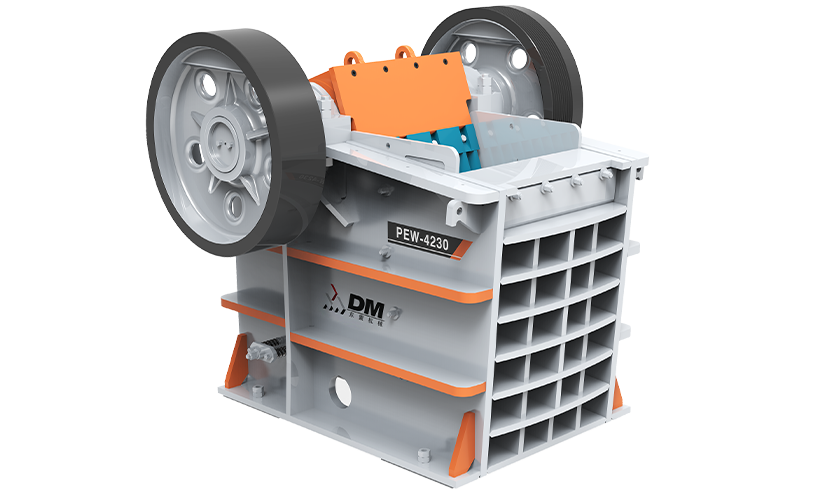

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!