Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

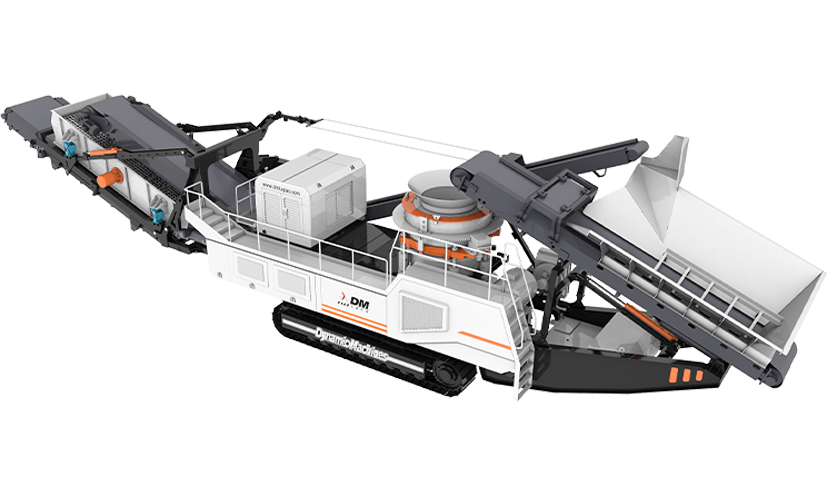

In the mining and construction industries, durability is a critical factor for machinery performance. Mobile Impact Crusher Factory equipment is designed to endure high-intensity crushing operations, often dealing with abrasive materials such as rocks, concrete, and recycled aggregates. Ensuring that the equipment maintains wear resistance during continuous operation is vital for both operational efficiency and cost-effectiveness. Wear-related failures can cause unscheduled downtime, increased maintenance costs, and reduced productivity. Consequently, factories implement several strategies in design, material selection, and maintenance planning to improve equipment longevity.

One of the fundamental approaches to enhancing wear resistance is selecting materials with high hardness and toughness for critical components. In mobile impact crushers, the rotor, blow bars, impact plates, and wear liners are particularly susceptible to abrasion. Factories often utilize high-chromium steel alloys or manganese steel for these parts due to their good combination of hardness, toughness, and resistance to fatigue. Additionally, some components may undergo surface treatments such as heat treatment, hard-facing, or coating with wear-resistant materials to further extend service life.

Beyond material selection, the structural design of components plays a significant role in reducing wear. Mobile impact crushers are engineered to distribute impact forces evenly across the rotor and impact surfaces, reducing localized stress points that accelerate abrasion. The geometry of blow bars and impact plates is carefully calculated to optimize the angle of impact, allowing materials to break efficiently while reducing excessive contact with high-wear areas. Advanced finite element analysis (FEA) and computer simulations are often employed to predict stress concentrations and guide design improvements.

Precision manufacturing processes also contribute to the durability of equipment. Tight tolerances in machining and assembly ensure that components fit correctly, reducing vibration and uneven force distribution that can cause premature wear. Factories typically implement rigorous quality control checks throughout production, including hardness testing, dimensional verification, and inspection for surface defects. Ensuring each component meets stringent standards reduces the likelihood of failure during heavy-duty operations.

Even with materials and design, preventive maintenance is essential to preserve wear resistance. Regular inspections, lubrication, and timely replacement of wear-prone parts help maintain suitable performance. Mobile impact crusher operators are often trained to monitor indicators such as unusual vibration, noise, or changes in product size distribution, which may signal excessive wear. Scheduled maintenance programs allow components to be replaced before failure occurs, preventing costly downtime and ensuring continuous operation.

Modern mobile impact crushers may incorporate additional technologies to reduce wear. Some designs feature adjustable impact plates or reversible blow bars, allowing operators to rotate or reposition components to improve their lifespan. Hydraulic adjustment systems can also control the distance and angle between the rotor and impact surfaces, optimizing impact conditions to reduce abrasion. These innovations enhance equipment durability while maintaining high crushing efficiency.

Ensuring wear resistance in mobile impact crushers requires a combination of careful material selection, optimized component design, precise manufacturing, and proactive maintenance. Mobile Impact Crusher Factory integrates these strategies into the production process, allowing the equipment to withstand high-intensity operations and abrasive materials without frequent failures. By addressing wear at both the engineering and operational levels, factories can deliver durable, reliable crushers that maintain productivity and reduce maintenance costs over their operational lifespan.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!