Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

In the dynamic landscape of the construction and mining industries, the adaptability of machinery is a key factor in determining its efficiency and utility. The China Stationary Crusher, as its name suggests, is primarily designed for stationary use, yet the question of its mobility and the ease of transferring it to different work sites is a topic of interest for many operators. This article delves into the mobility aspects of the China Stationary Crusher, discussing its design, the challenges associated with relocation, and the strategies employed to facilitate its movement when necessary.

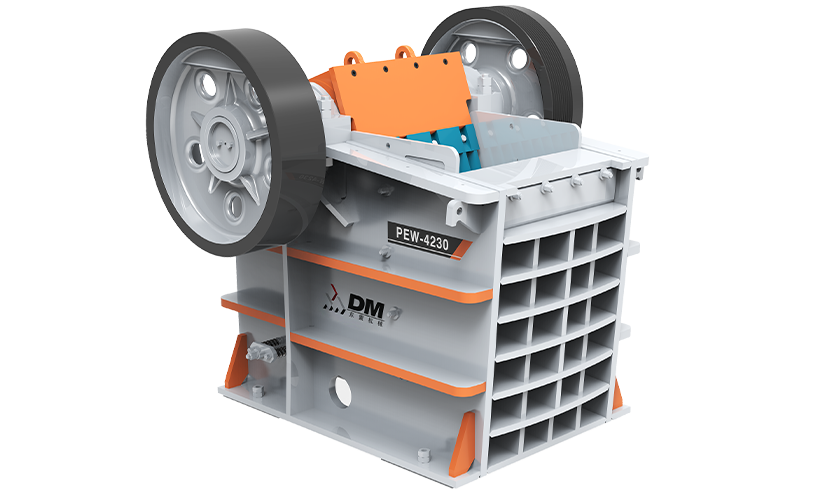

The China Stationary Crusher is engineered to provide robust and reliable crushing capabilities in a fixed location. Its immobility is a result of its heavy structure, which is designed to withstand the immense forces generated during the crushing process. The stationary nature of these crushers is a testament to their stability and the high torque they can deliver, making them ideal for large-scale operations where the material to be crushed is consistently sourced from a single location.

However, the need to transfer a China Stationary Crusher to a new work site can arise due to various reasons, such as the depletion of resources at the current site or the need to follow a moving resource, such as a mining operation. The mobility of these crushers is therefore a critical consideration for operators who require flexibility in their operations. Despite their stationary design, there are instances where the China Stationary Crusher can be moved, albeit with significant logistical challenges.

The process of relocating a China Stationary Crusher involves disassembling the machine into its major components, which can be a complex and time-consuming task. The heavy weight of these components requires specialized heavy-lifting equipment, such as cranes and flatbed trucks, to transport them to the new site. Once at the new location, the components must be reassembled, a process that requires skilled technicians and precise alignment to ensure the crusher operates efficiently.

In addition to the physical challenges of moving a China Stationary Crusher, there are also logistical considerations. The transportation of such large and heavy machinery can be restricted by road regulations, bridge weight limits, and other infrastructure constraints. This often necessitates the planning of specific routes and, in some cases, the use of alternative transportation methods, such as rail or sea, which can add to the cost and complexity of the relocation.

To enhance the mobility of China Stationary Crusher, some manufacturers have developed designs that allow for easier disassembly and reassembly. Modular components and the use of standardized parts can simplify the relocation process, making it more feasible for operators who need to move their crushers frequently. Additionally, the development of portable or semi-mobile versions of these crushers can offer a solution for those who require greater flexibility in their operations.

In conclusion, while the China Stationary Crusher is primarily designed for stationary use, there are scenarios where its mobility becomes a crucial factor. The relocation of these crushers is a complex process that involves disassembly, transportation, and reassembly, each step presenting its own set of challenges. However, with careful planning, the use of specialized equipment, and the adoption of modular designs, the mobility of China Stationary Crusher can be improved, allowing operators to adapt to changing work site conditions and resource availability.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!