Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

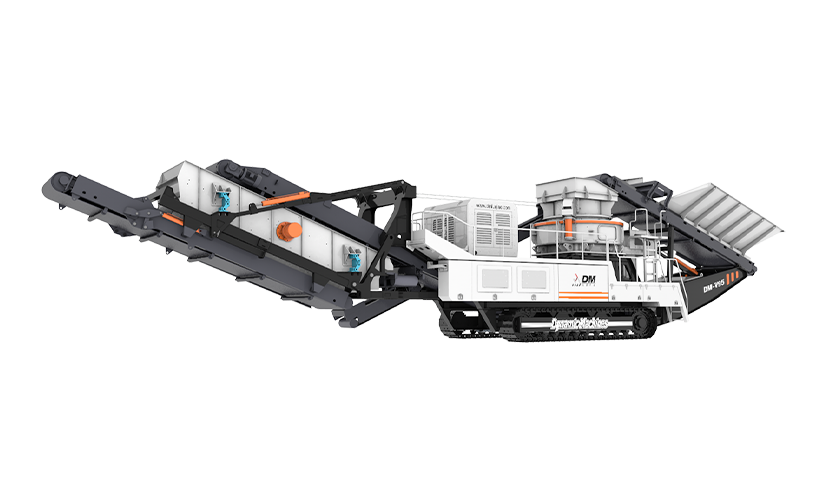

A Mobile Crusher Factory specializes in producing mobile crushing equipment designed for flexible, on-site material processing. Compared to traditional fixed crushers, mobile crushers offer distinct benefits and some limitations. Understanding these differences helps operators select the right equipment for specific mining, construction, or aggregate applications, balancing efficiency, cost, and operational convenience.

Mobile crushers can be easily transported to different job sites. This eliminates the need to transport raw materials over long distances, saving on logistics costs and time. Fixed crushers require permanent installation, which limits their operational flexibility.

Mobile crushers are designed for rapid deployment. Minimal foundation work is needed, and they can start crushing immediately after reaching the site. Fixed crushers often require extensive civil work and foundation construction, causing longer project preparation times.

Because mobile crushers are brought directly to the material, they reduce the need for additional conveyors or haul trucks. This decreases fuel consumption, labor requirements, and overall operational costs compared to stationary setups.

Mobile crushers can handle a variety of materials, including rock, ore, construction debris, and recycled concrete. Adjustable configurations allow operators to switch between primary, secondary, and even tertiary crushing stages on the same machine.

Mobile crusher units can be deployed in multiple numbers across large sites to scale production quickly. Fixed plants require substantial capital investment for additional units and may take longer to expand capacity.

Lower Capacity Compared to Fixed Crushers:

Mobile crushers generally have smaller feed openings and lower throughput than large fixed crushing plants. For high-volume operations, fixed crushers may provide more consistent output over long periods.

Higher Wear and Maintenance Costs:

Mobile crushers operate in varying terrains and conditions, which can accelerate wear on tires, tracks, and movable components. Maintenance frequency may be higher compared to stationary equipment.

Limited Crushing Options:

Although versatile, mobile crushers may not offer as many specialized crushing configurations as a fixed plant with dedicated jaw, cone, and impact crushers for each stage. This can affect the precision of particle size distribution in complex operations.

Energy Consumption:

Mobile crushers often rely on diesel engines for mobility and power. While convenient for remote sites, fuel consumption can be higher compared to electrically powered fixed crushers connected to the grid.

Initial Investment Costs:

Mobile units may have higher upfront costs per unit of capacity due to the integration of mobility systems, hydraulic drives, and on-board conveyors. Fixed crushers, while larger in size, may have a lower cost per ton of capacity when fully utilized.

A Mobile Crusher Factory produces equipment that offers flexibility, rapid deployment, reduced material handling, and versatile applications, making it ideal for temporary sites, remote locations, and smaller operations. However, mobile crushers also face limitations such as lower capacity, higher wear, limited specialized configurations, and potentially higher energy costs. Operators must weigh these advantages and disadvantages against project requirements, material characteristics, and production goals. By understanding the specific benefits and trade-offs of mobile versus fixed crushers, companies can optimize crushing operations, reduce costs, and improve efficiency across diverse applications.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!