Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

A Stone Crushing Machine Factory produces equipment designed to handle a variety of rocks, ores, and aggregates. One of the common operational challenges is processing wet or sticky materials. High moisture content, clay-rich ores, and fine cohesive particles can drastically affect crusher efficiency, throughput, and wear on components. Understanding how wet conditions influence crushing performance allows operators to implement strategies that maintain consistent output while reducing downtime.

1. Material Adhesion and Build-Up:

Wet or sticky materials tend to adhere to the crusher walls, feed hopper, and conveyor belts. This can reduce the volume of material entering the crushing chamber and disrupt the flow, resulting in inconsistent feed and lower production rates.

2. Clogging and Bridging:

Sticky materials can form bridges or blockages within the crushing chamber. In jaw crushers or cone crushers, this can halt operations, requiring manual clearing or hydraulic intervention. Such interruptions reduce overall efficiency and increase operational costs.

3. Reduced Fracture Efficiency:

Moisture increases the ductility of certain rocks, making them deform rather than fracture under pressure. This effect can cause larger-than-desired particle sizes, lower throughput, and increased energy consumption.

Controlled Feeding:

Ensuring a consistent feed rate is essential for preventing material build-up and bridging. Vibratory feeders, inclined hoppers, or pre-screening systems can help maintain a uniform flow into the crusher.

Appropriate Crusher Selection:

Vertical shaft impact crushers and specialized wet material crushers perform better with sticky or high-moisture materials compared to conventional jaw or cone crushers. Selecting the right crusher type improves crushing efficiency and reduces operational problems.

Adjustment of Crusher Settings:

Operators can optimize the closed-side setting or crushing gap to better handle wet materials. Slightly larger settings may prevent clogging while still achieving an acceptable particle size distribution.

Wet materials accumulate quickly in the crusher chamber, hoppers, and conveyor systems. Regular cleaning prevents build-up, reduces blockages, and ensures stable production.

Moist and abrasive materials accelerate wear on jaw plates, liners, and impellers. Regular inspections and timely replacement of wear parts help maintain crusher efficiency and prevent unscheduled downtime.

Wet conditions can affect hydraulic systems and lubrication, especially if slurry or dust enters sensitive areas. Proper sealing and routine checks of lubrication systems reduce the risk of component failure.

Wet or sticky materials present unique challenges for a Stone Crushing Machine Factory, including adhesion, clogging, reduced fracture efficiency, and accelerated wear. By implementing controlled feeding, selecting appropriate crushers, adjusting settings, and performing diligent maintenance, operators can maintain high efficiency even under challenging conditions. Additional strategies such as pre-screening, anti-stick coatings, and proper stockpiling further enhance performance. Understanding material behavior in wet conditions and applying these operational techniques ensures reliable, consistent output while extending equipment lifespan.

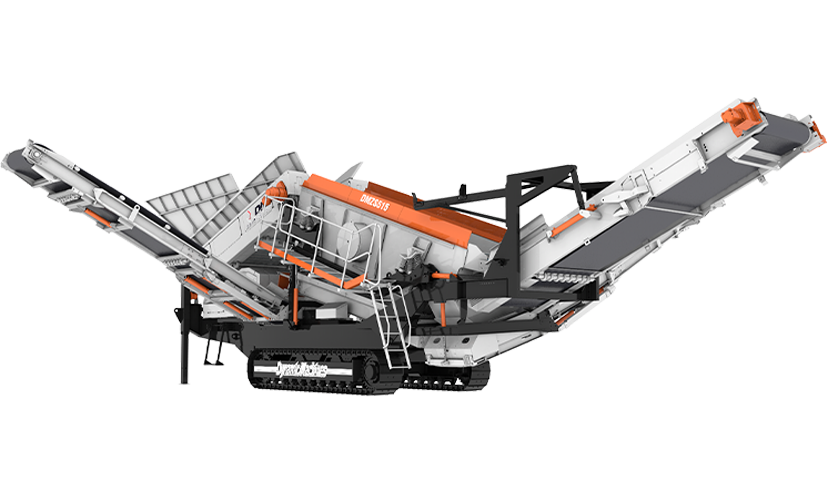

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!