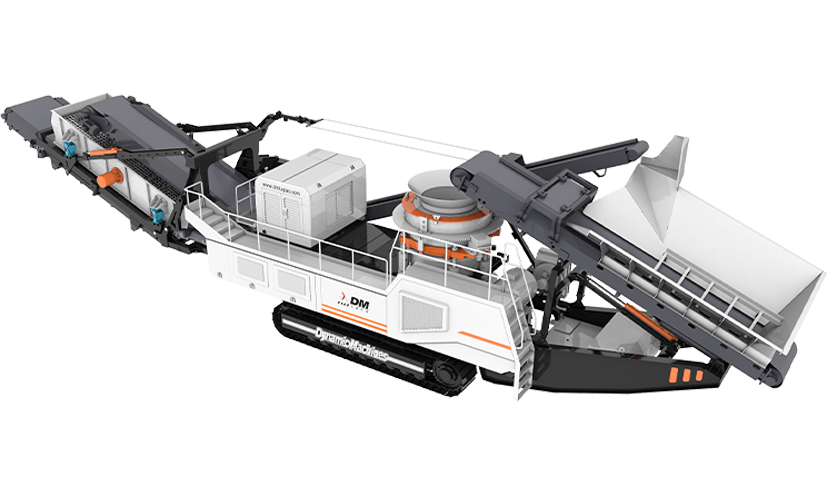

Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

The Challenge of High Humidity

High-humidity environments present unique challenges for crushing operations. The Mobile Impact Crusher Factory must consider how moisture in raw materials, ambient conditions, and equipment surfaces can affect efficiency. Excessive moisture can cause material clumping, increased wear on components, and reduced throughput. Understanding these factors is essential for optimizing performance, maintaining consistent production rates, and prolonging machine lifespan.

1. Material Clumping and Adhesion

High moisture content causes fine particles to stick together, forming clumps that are harder to feed into the crusher.

Clumped materials can block the feed hopper or choke the crushing chamber, causing inconsistent output and lower efficiency.

2. Effect on Feed Uniformity

Non-uniform feeding caused by wet materials may result in uneven crushing forces.

This inconsistency can reduce particle size uniformity and increase the load on the rotor and blow bars.

3. Increased Transportation Resistance

Moist material has higher cohesion and friction, slowing down conveyor belts and feeder systems.

Additional energy is required to move wet material, slightly increasing operational costs.

1. Rotor and Blow Bar Wear

Moisture mixed with abrasive particles accelerates wear on the rotor, blow bars, and impact plates.

Frequent inspections and timely replacement of these parts are necessary to maintain efficiency.

2. Potential for Material Buildup

Wet materials tend to stick to the internal surfaces of the crushing chamber.

This buildup can reduce crushing volume and efficiency, requiring periodic cleaning during production.

3. Increased Risk of Slippage

High humidity can make conveyor belts and feeder rollers slippery, reducing feed consistency.

Proper maintenance and adjustments are critical to avoid operational downtime.

1. Optimized Rotor Speed and Configuration

Adjustable rotor speed allows the crusher to handle wet materials without excessive clumping.

Rotor design with adequate clearance helps prevent material from sticking to moving parts.

2. Anti-Clogging Feed Systems

Vibrating feeders or pre-screening mechanisms ensure a steady and uniform flow of materials.

These systems reduce the chance of feed blockages and maintain consistent crushing efficiency.

3. Moisture-Resistant Coatings

Components coated with wear-resistant and moisture-repellent materials reduce adhesion.

Coatings extend the lifespan of critical parts and help maintain high operational efficiency.

1. Monitoring Moisture Content

Regular measurement of material moisture allows operators to anticipate potential feeding and crushing issues.

Pre-drying or partial blending of wet materials can help maintain a uniform feed.

2. Adjusting Operational Parameters

Slower feed rates and optimized rotor speeds prevent overloading the crusher.

Adjusting the gap between the rotor and impact plates can improve material discharge and particle uniformity.

3. Scheduled Maintenance and Cleaning

Frequent inspections of the crushing chamber prevent buildup and maintain consistent efficiency.

Cleaning schedules must be adapted to environmental humidity levels to avoid unexpected downtime.

High humidity can impact the performance of a Mobile Impact Crusher Factory by affecting material flow, increasing wear, and causing blockages. However, through careful design, operational adjustments, and proactive maintenance, these challenges can be mitigated. Optimized rotor configurations, anti-clogging feed systems, and moisture-resistant coatings improve the handling of wet materials. Monitoring moisture content and adapting operational parameters further ensures consistent throughput. By implementing these strategies, manufacturers can maintain high efficiency and reliable production even under challenging high-humidity conditions.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!