Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

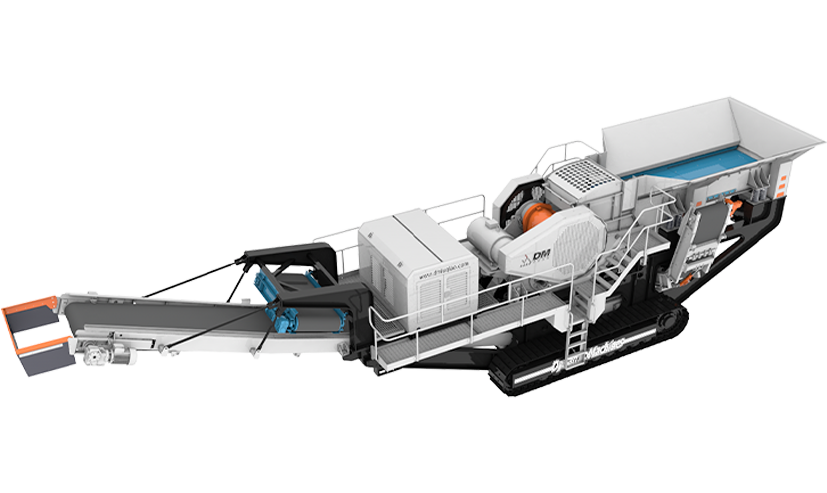

Energy efficiency has become a critical issue in the construction, mining, and recycling industries. Heavy machinery, such as crushers, traditionally consumes large amounts of fuel or electricity, causing high operating costs and environmental concerns. As companies seek more sustainable solutions, the question arises: how do modern mobile impact crushers perform compared to conventional stationary crushers? A Mobile Impact Crusher Factory must address this challenge by designing machines that reduce energy usage without compromising productivity.

Conventional crushing systems are usually installed at fixed plants. They require large amounts of energy not only to power the machinery but also to support additional processes such as material transport, secondary crushing, and screening. This setup involves:

Mobile impact crushers are engineered with designs that directly target energy savings. Their efficiency can be seen in several areas:

In practical applications, mobile impact crushers can achieve energy savings ranging from 10% to 25% compared to traditional setups. The degree of savings depends on the type of material, site conditions, and operator practices. For example:

Lower energy consumption creates advantages that extend beyond cost savings. Mobile impact crushers also contribute to:

A Mobile Impact Crusher Factory continues to introduce technologies that enhance energy efficiency:

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!