Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

The China Hydraulic Cone Crusher, known for its efficiency and reliability in the crushing industry, demands a meticulous maintenance and care regimen to ensure its longevity and suitable performance. This robust machine, widely used in mining and construction sectors, requires regular attention to keep it running smoothly and safely. Understanding the intricacies of its maintenance is crucial for operators and maintenance crews to improve the efficiency of the China Hydraulic Cone Crusher.

To start with, regular inspection of the China Hydraulic Cone Crusher is paramount. This includes checking the wear and tear on the crushing chamber, the wear plates, and the mantle. Any signs of excessive wear should be addressed immediately to prevent further damage to the machine. The lubrication system of the China Hydraulic Cone Crusher should also be monitored closely. Adequate lubrication is essential to reduce friction and heat, thereby extending the life of the crusher's components.

The hydraulic system of the China Hydraulic Cone Crusher is another critical area that requires routine maintenance. Regularly checking the pressure and cleanliness of the hydraulic oil is essential to prevent leaks and ensure the crusher's smooth operation. Any contamination in the hydraulic system can cause erratic behavior and potential damage to the China Hydraulic Cone Crusher.

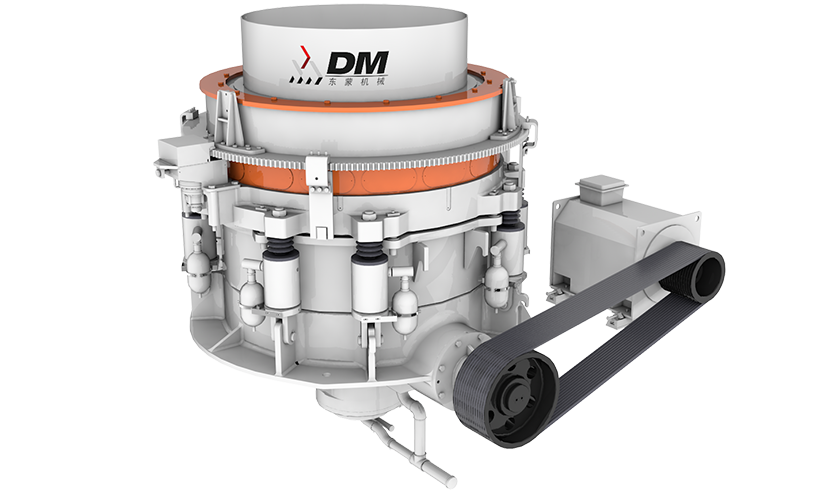

When it comes to the China Hydraulic Cone Crusher's belts and pulleys, they should be inspected for any signs of wear, misalignment, or damage. Proper tension and alignment are crucial for the efficient transmission of power from the motor to the crushing mechanism. Loose or damaged belts can cause reduced crushing efficiency and potential downtime.

The electrical components of the China Hydraulic Cone Crusher should not be overlooked. Regular checks for any signs of corrosion, damage, or loose connections are essential to prevent electrical faults. The motor and control panels should be kept clean and dry to avoid any short circuits or electrical hazards.

Thermal management is another aspect that requires attention when maintaining the China Hydraulic Cone Crusher. Overheating can cause reduced performance and potential damage to the crusher's components. Regularly checking the temperature of the crusher and ensuring proper cooling systems are in place can help prevent overheating issues.

The feed material to the China Hydraulic Cone Crusher should also be monitored. Tramp metal or oversized rocks can cause significant damage to the crusher, resulting in costly repairs and downtime. Installing a metal detector or a magnetic separator can help in preventing such foreign objects from entering the crusher.

Lastly, a well-documented maintenance schedule is crucial for the China Hydraulic Cone Crusher. Keeping a record of all maintenance activities, including lubricating, inspections, and repairs, can help in identifying patterns and anticipating future maintenance needs. This proactive approach can significantly reduce downtime and extend the life of the China Hydraulic Cone Crusher.

In conclusion, the proper maintenance and care of the China Hydraulic Cone Crusher are essential for its suitable performance and longevity. By following a comprehensive maintenance regimen that includes regular inspections, lubrication, hydraulic system care, belt and pulley checks, electrical component maintenance, thermal management, and proper feed material control, operators can ensure the China Hydraulic Cone Crusher remains a reliable and efficient workhorse in their operations.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!