Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

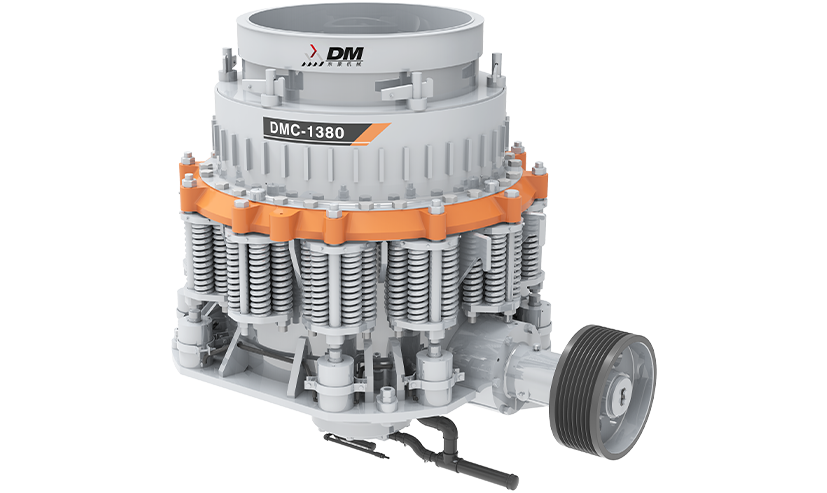

The China Hydraulic Cone Crusher is a sophisticated piece of equipment that has changed the field of mineral processing due to its advanced crushing capabilities. A key component of this technology is the hydraulic system, which plays a crucial role in the operation, safety, and performance of the crusher. This article delves into the intricacies of how the hydraulic system within the China Hydraulic Cone Crusher functions, highlighting its importance in ensuring the crusher's efficiency and reliability.

The hydraulic system of the China Hydraulic Cone Crusher is an essential part of its design, providing the necessary force to adjust the crusher's main components and maintain the crushing pressure. This system is composed of several key elements, including hydraulic pumps, valves, cylinders, accumulators, and a control system. The pumps are responsible for circulating hydraulic fluid throughout the system, which is then directed to the various actuators by the valves.

In operation, the hydraulic system of the China Hydraulic Cone Crusher works in tandem with the crusher's mechanical components to achieve suitable crushing performance. When the crusher is in use, the hydraulic system applies pressure to the mainframe, allowing it to adjust to the size of the material being crushed. This adjustment is critical for maintaining the crusher's efficiency and for preventing damage to the machine from oversized or unbreakable objects.

One of the primary functions of the hydraulic system in the China Hydraulic Cone Crusher is to provide tramp iron relief. Tramp iron or foreign objects that are not meant to be crushed can cause significant damage to the crusher. The hydraulic system is designed to detect the presence of tramp iron and relieve the pressure, preventing damage to the crusher's internal components. This feature is a testament to the advanced engineering that goes into the design of the China Hydraulic Cone Crusher.

Another important aspect of the hydraulic system in the China Hydraulic Cone Crusher is its role in adjusting the crusher's closed-side setting (CSS). The CSS is the distance between the mantle and the bowl liner. This setting can be adjusted to control the size of the crushed material. The hydraulic system allows for easy and precise adjustments to the CSS, ensuring that the crusher can produce material of the desired size.

The hydraulic system also plays a vital role in the safety features of the China Hydraulic Cone Crusher. It is equipped with safety devices such as pressure relief valves and emergency stop systems that can quickly shut down the crusher in case of an overload or system failure. This prevents damage to the crusher and ensures the safety of the operators.

Maintenance of the hydraulic system in the China Hydraulic Cone Crusher is crucial for its longevity and performance. Regular checks and replacements of hydraulic fluid, as well as the inspection of hoses and seals, are necessary to prevent leaks and maintain suitable pressure within the system. The system's design also allows for easy access to these components, facilitating maintenance and repair.

In conclusion, the hydraulic system is an integral part of the China Hydraulic Cone Crusher's operation, providing the force needed for adjustments, tramp iron relief, and CSS control. It also plays a significant role in the safety features of the crusher. Understanding how the hydraulic system works is essential for operators and maintenance personnel to ensure the crusher's suitable performance and longevity. As the China Hydraulic Cone Crusher continues to be a guiding choice in the crushing industry, the sophistication of its hydraulic system remains a key factor in its success.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!