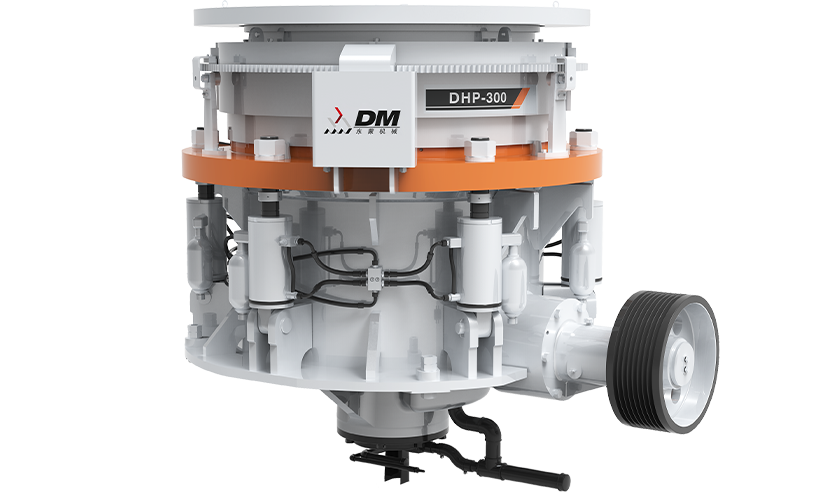

Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

Understanding Discharge Size and Its Impact

The discharge size in any crushing operation directly affects the quality, consistency, and applicability of the final product. Whether producing aggregates for construction or finely crushed material for industrial processing, maintaining a suitable particle size is essential. In this regard, the Custom Hydraulic Cone Crusher offers multiple precise and efficient methods to adjust discharge size, giving operators better control over final output.

Hydraulic Adjustment Mechanism

One of the standout features of a Custom Hydraulic Cone Crusher is its built-in hydraulic adjustment system. This system allows for fast, on-the-fly modification of the closed side setting (CSS), which is the small gap between the mantle and concave. Adjusting the CSS controls the size of the output material: a narrower CSS produces finer material, while a wider CSS results in coarser discharge. The adjustment can usually be done automatically or remotely, without the need to shut down the crusher, significantly reducing downtime and improving operational flexibility.

Role of the Main Frame and Piston

In traditional cone crushers, adjusting the CSS requires manual intervention or mechanical tools. By contrast, the Custom Hydraulic Cone Crusher utilizes a main frame supported by a hydraulic piston. When adjustment is needed, the piston moves vertically to shift the position of the main shaft, effectively changing the CSS. This design offers far greater responsiveness and precision than spring-based systems, ensuring output size remains consistent even as wear occurs or feed conditions change.

Automatic Control Systems

Many modern Custom Hydraulic Cone Crushers come equipped with smart control systems that monitor variables such as motor load, oil pressure, and wear levels in real time. These systems can automatically adjust the CSS to maintain a targeted discharge size, compensating for material variations or liner wear. This not only improves consistency but also protects the machine from potential overload or underperformance.

Feed Characteristics and Their Influence

The characteristics of the input material—such as hardness, moisture content, and particle shape—can also influence discharge size. Softer materials are easier to crush to finer sizes, while harder or more abrasive materials may require different settings to avoid premature wear or suboptimal output. The Custom Hydraulic Cone Crusher is typically engineered with variable cavity designs and adjustable operating parameters, enabling it to adapt to different feed types while maintaining desired discharge specifications.

Interchangeable Crushing Cavities

Another important design feature that helps regulate discharge size is the availability of different crushing cavity configurations. Operators can choose from fine, medium, or coarse cavities depending on production needs. These interchangeable cavity designs are tailored for different reduction ratios and product sizes, making the Custom Hydraulic Cone Crusher suitable for a wide range of applications.

Maintaining Accuracy Over Time

To sustain precise discharge sizing over time, regular inspection and maintenance of wear parts such as liners and the cone head are crucial. Even with advanced hydraulic systems, worn components can cause inconsistent output sizes. Scheduled liner changes and system recalibrations ensure that the crusher continues to perform at its designed efficiency level.

Conclusion

Controlling discharge size in a Custom Hydraulic Cone Crusher involves a combination of hydraulic CSS adjustment, intelligent control systems, feed evaluation, and cavity selection. Together, these elements provide operators with a reliable and flexible solution to meet the specific size requirements of various materials and industries. By understanding and leveraging these adjustment methods, producers can achieve better product quality, higher efficiency, and improved overall performance.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!