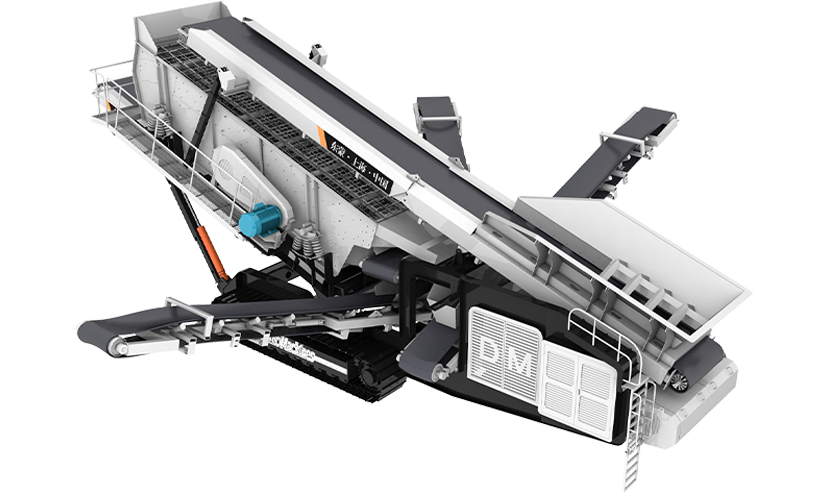

Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

In heavy-duty industries such as mining, construction, and recycling, crushing machines face demanding conditions every day. Equipment must withstand constant impact, abrasive materials, and prolonged operation without failure. A Mobile Impact Crusher Factory, when designing and manufacturing machines, places durability and stability at the center of production. Without these qualities, productivity drops, maintenance costs rise, and the overall reliability of a project can be compromised.

One of the key ways to guarantee durability is through the careful choice of raw materials and reinforced components.

Durability is not only about strong materials but also about smart engineering. Modern mobile impact crushers integrate design elements that enhance stability:

A Mobile Impact Crusher Factory ensures durability and stability through strict quality assurance during manufacturing:

For crushers, stability means consistent performance under varying loads and conditions. Manufacturers achieve this by:

Even the durable equipment requires maintenance. Stability is further ensured through:

The future of durability and stability in mobile impact crushers lies in technology. Ongoing advancements include:

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!