Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

As construction and demolition activities accelerate worldwide, concrete waste has become a pressing environmental challenge. Recycling this material into reusable aggregates is no longer an option but a necessity for sustainable growth. In this context, the role of a Mobile Impact Crusher Factory is crucial, as it provides advanced equipment designed to transform construction debris into high-quality recycled aggregates suitable for use in new building projects.

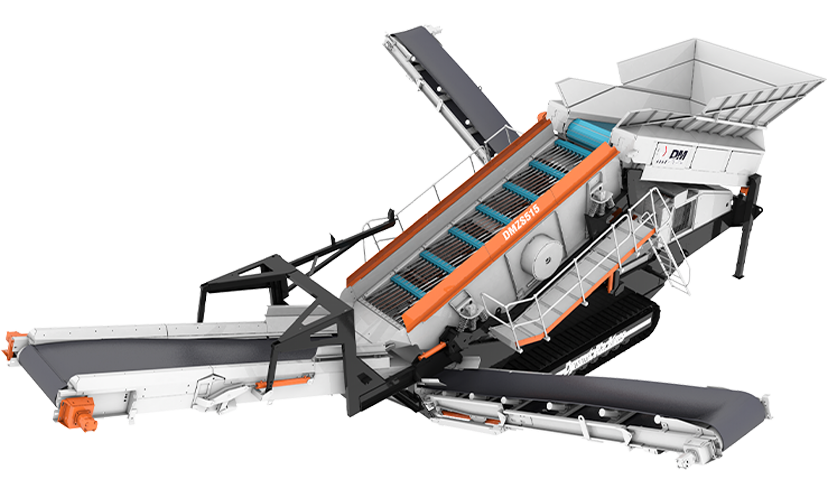

The efficiency of mobile impact crushers in concrete recycling can be measured by their ability to streamline processes and minimize waste. Unlike stationary crushers, mobile units can be transported directly to demolition or construction sites, reducing the need for hauling heavy debris. This mobility provides several advantages:

Lower transportation costs: Waste material is processed at the location where it is generated, saving time and fuel.

Rapid deployment: Units can be set up quickly, allowing immediate recycling work to begin.

Flexibility in capacity: Machines can be scaled up or down depending on the project's size.

By integrating these features, operators achieve both cost savings and improved overall recycling efficiency.

One of the significant measures of efficiency is the quality of the recycled aggregates produced. Modern mobile impact crushers are designed to deliver uniform particle sizes and reduce contaminants such as rebar or embedded debris. This allows the recycled material to be used confidently in a variety of applications, from road base layers to ready-mix concrete production. With advanced rotor systems, adjustable settings, and precision screening, these machines ensure that output consistently meets industry standards.

The role of mobile impact crushers extends beyond economics into sustainability. Their operation supports multiple environmental benefits:

Reduction in natural resource use: Recycling concrete decreases reliance on quarrying and the extraction of virgin aggregates.

Energy savings: Processing waste requires less energy compared to producing fresh materials.

Lower emissions: On-site crushing reduces the need for extensive transport, directly cutting carbon footprints.

Compliance with green building standards: Many governments and certification programs now require recycling as part of sustainable construction initiatives.

Mobile impact crushers continue to evolve with technology. Factories producing these machines are increasingly focusing on innovations that enhance efficiency, such as:

While mobile impact crushers offer many benefits, efficiency can still be influenced by certain challenges:

The demand for recycled concrete aggregates is expected to rise as urbanization and infrastructure development continue. Mobile impact crushers will play an even larger role in meeting this demand efficiently. With continuous technological advancements and a growing focus on eco-friendly design, future models will likely deliver higher output with reduced energy consumption, making them indispensable for a circular construction economy.

The efficiency of mobile impact crushers in concrete recycling and aggregate production is evident in their ability to provide cost-effective, environmentally friendly, and high-quality solutions. By enabling on-site processing, producing uniform recycled materials, and supporting sustainability targets, these machines have become a cornerstone of modern construction practices. With ongoing innovation and global demand for sustainable resources, their role will only grow stronger in shaping the future of the construction industry.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!