Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

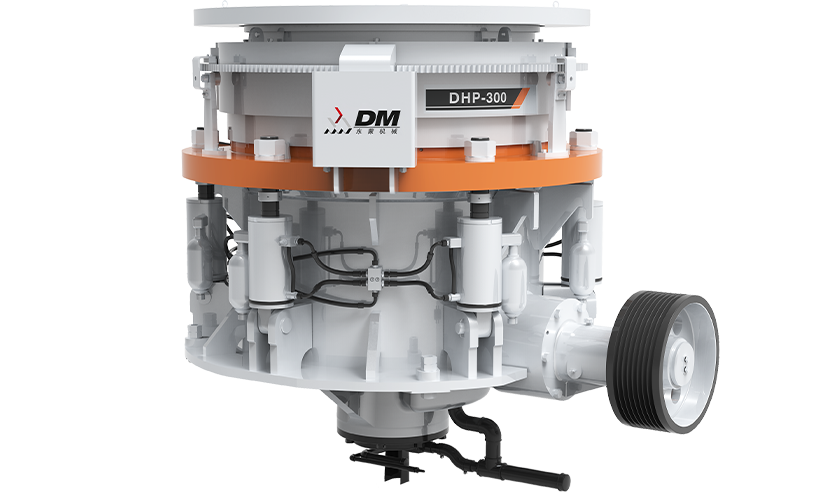

In the heavy machinery industry, noise pollution is a significant concern, particularly with equipment like the China Hydraulic Cone Crusher. These crushers are renowned for their efficiency in crushing hard and abrasive materials, but their operation can generate substantial noise levels that warrant close examination. This article aims to explore the noise characteristics of China Hydraulic Cone Crushers and discuss measures taken to mitigate the acoustic impact of these machines.

The China Hydraulic Cone Crusher, a key component in the mining and quarrying sectors, is designed to withstand the rigors of heavy-duty crushing. Despite its construction and performance, the noise generated during operation can reach levels that are not only disruptive but also potentially harmful to the health of workers in the vicinity. Noise levels of China Hydraulic Cone Crushers are influenced by several factors, including the crusher's design, the materials being crushed, the speed of operation, and the overall maintenance status of the machine.

When assessing the noise levels of a China Hydraulic Cone Crusher, it's important to consider the decibel (dB) scale. A typical China Hydraulic Cone Crusher operates at noise levels that can range from 80 to 90 dB, depending on the model and the specific crushing process. Such levels are comparable to those of a large truck passing by or a loud factory environment, which can cause hearing damage if exposure is prolonged without proper protective measures.

To address the noise issue, manufacturers of China Hydraulic Cone Crushers have implemented various design modifications. One such modification is the use of noise-reduction technologies, such as soundproofing materials and enclosures that can help to dampen the noise emitted by the machine. Additionally, the incorporation of advanced hydraulic systems in modern China Hydraulic Cone Crushers has contributed to a more controlled and quieter crushing process, as hydraulics can absorb some of the shock and vibration that typically cause noise.

Another approach to reducing the noise levels of China Hydraulic Cone Crushers is through regular maintenance. Ensuring that all components are in good working order, such as lubricating the bearings and replacing worn parts, can significantly lower the operational noise. Proper maintenance not only helps in noise reduction but also extends the life of the crusher and improves its overall efficiency.

Environmental regulations also play a role in managing the noise levels of China Hydraulic Cone Crushers. In many countries, there are strict guidelines for the allowable noise levels at construction and mining sites. Compliance with these regulations often requires the use of additional noise control measures, such as noise barriers or the installation of silencers near the exhaust systems of the crushers.

Furthermore, the placement of China Hydraulic Cone Crushers within a facility can impact the overall noise levels. Strategically positioning the crushers in areas that are less populated or using natural barriers to block the sound can be effective noise management strategies. Additionally, the use of noise monitoring systems can help operators to identify when noise levels are reaching unacceptable levels, prompting adjustments to the operation or the implementation of further noise reduction measures.

In conclusion, the noise levels of China Hydraulic Cone Crushers are a significant consideration for both operators and the surrounding environment. While these machines are known for their crushing capabilities, it is essential to recognize and address the associated noise pollution. By employing a combination of design enhancements, regular maintenance, adherence to environmental regulations, and strategic placement, the noise levels of China Hydraulic Cone Crushers can be effectively managed, ensuring a safer and more comfortable working environment for all involved.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!