Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

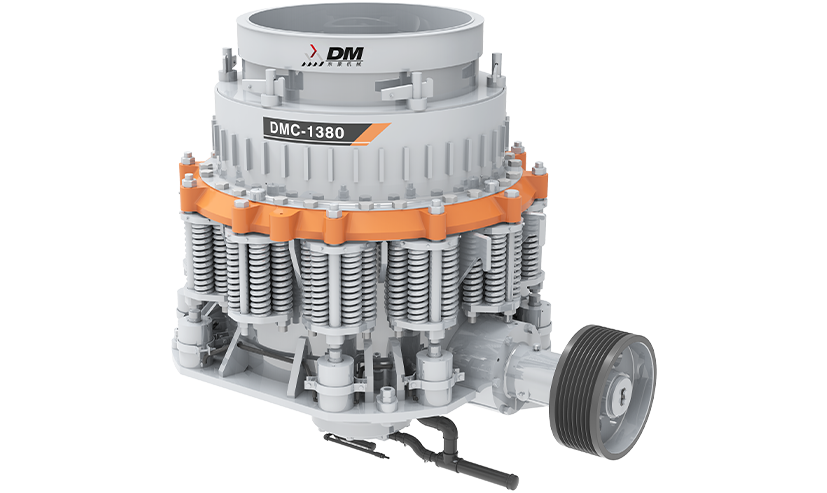

Crushing Force and Structural Stability

When it comes to processing high-hardness materials such as basalt, granite, iron ore, and quartzite, crushing equipment must deliver good force, durability, and precision. A Custom Hydraulic Cone Crusher is engineered to meet these demands with its advanced design and robust construction. Unlike traditional crushers, it delivers consistent crushing performance even under extreme pressure, thanks to its heavy-duty frame and reinforced components. The strong structural integrity reduces deformation under load, ensuring long-term reliability when handling abrasive and dense materials.

Efficient Hydraulic System for Constant Crushing Power

One of the key advantages of the Custom Hydraulic Cone Crusher is its hydraulic system, which maintains constant pressure and crushing force during operation. This is particularly critical for high-hardness materials, which require greater energy input to break down. The hydraulic cylinders automatically adjust to changes in material hardness or feed conditions, ensuring a steady throughput and uniform particle size. This dynamic responsiveness reduces production fluctuations, even when material quality varies.

Wear-Resistant Components

High-hardness materials are known to accelerate wear in traditional crushing machines. In contrast, the Custom Hydraulic Cone Crusher is equipped with specially treated wear-resistant liners, mantles, and concaves made from high-manganese steel or composite alloys. These components are designed to withstand repeated impact and grinding without premature failure. In addition, the design often includes easy-to-replace wear parts and optimized liner profiles to reduce replacement frequency and maintenance costs over time.

Consistent Output and Particle Size Control

In high-hardness applications, maintaining control over the final product size can be challenging. The advanced closed side setting (CSS) adjustment feature in a Custom Hydraulic Cone Crusher enables operators to fine-tune the output size precisely, even under heavy load. This level of control results in uniform particle distribution, which is essential for meeting strict product specifications in construction or mineral processing.

Overload Protection and Automation

Processing extremely hard materials carries the risk of sudden overloads or uncrushable items entering the chamber. The integrated overload protection system in a Custom Hydraulic Cone Crusher quickly responds to such conditions by releasing pressure and lifting the main shaft to allow foreign materials to pass. This prevents potential damage and unplanned downtime. Additionally, many modern hydraulic models include intelligent automation that monitors internal parameters such as load, oil temperature, and liner wear. These features allow the system to make real-time adjustments, maintaining efficiency and safety during continuous operation.

Energy Efficiency in Demanding Conditions

Crushing hard materials requires more energy, but the hydraulic cone crusher design helps optimize power usage. With high crushing efficiency and adjustable speed through variable frequency drives (VFD), the Custom Hydraulic Cone Crusher can match energy input to actual material requirements. This not only lowers operational costs but also reduces environmental impact, a growing concern in many industries today.

Conclusion

The Custom Hydraulic Cone Crusher is highly capable of handling high-hardness materials, offering a combination of crushing power, wear resistance, real-time adjustment, and automation. These features collectively provide consistent performance, longer service life, and lower operational disruptions. Whether used in mining, metallurgy, or aggregate production, it proves to be a reliable solution for some of the demanding crushing challenges in the industry.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!