Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

In today’s sand and gravel industry, producers must balance output capacity, product quality, operational flexibility, and cost control. A Mobile Impact Crusher has emerged as a practical solution that addresses these challenges in a single, integrated system. Compared with stationary crushing plants, mobile units require less infrastructure and can be deployed rapidly. Many aggregate suppliers cooperate directly with a reliable Mobile Impact Crusher Factory to obtain equipment tailored to specific material types, production targets, and site layouts, ensuring efficient and stable operations from the beginning.

One of the significant advantages of a mobile impact crushing system is its ability to produce high-quality aggregates. Impact crushing technology uses high-speed rotor impact and material collision to break stones, resulting in more cubic particles and fewer flaky or elongated fragments. This improved particle shape enhances the strength and workability of concrete and asphalt mixtures.

The adjustable discharge settings allow operators to control the final product size accurately, ensuring consistent grading that meets construction standards. In competitive aggregate markets, better particle shape and uniformity often translate into higher selling prices and stronger customer trust.

Mobility is a key advantage in aggregate production. Unlike fixed plants that require permanent foundations and complex installation, mobile impact crushers can be transported directly to quarries, construction sites, or demolition locations. This reduces the need for hauling raw materials over long distances, cutting fuel consumption and transportation expenses.

On-site crushing also improves project timelines. Equipment can be installed and commissioned quickly, allowing producers to respond faster to market demand. For operations involving multiple sites or temporary projects, the ability to relocate machinery enhances asset utilization and reduces downtime.

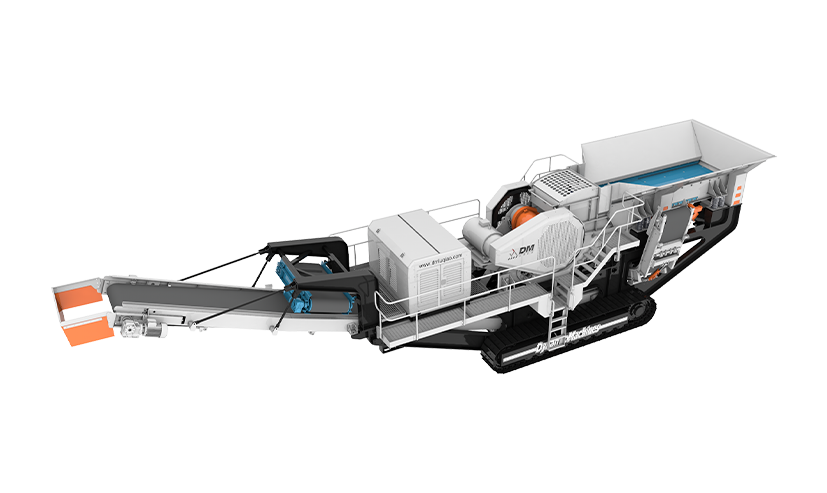

Mobile impact crushing plants are typically designed as compact, integrated systems that combine feeding, crushing, and sometimes screening functions. This streamlined configuration simplifies workflow and reduces coordination between separate machines. Centralized control systems help maintain stable feed rates and monitor operational parameters, improving overall efficiency.

Modern designs focus on energy efficiency and ease of maintenance. Accessible components reduce service time, while optimized power systems lower energy consumption. These factors contribute to higher productivity and reduced operating costs over the equipment’s lifespan.

From a financial perspective, mobile systems usually involve lower initial investment compared with establishing a full stationary crushing line. There is no need for extensive civil engineering work, which reduces setup costs. In addition, equipment purchased from an experienced Mobile Impact Crusher Factory often includes technical support and spare parts services, reducing long-term operational risks.

Environmental considerations are also increasingly important in aggregate production. Mobile impact crushers help reduce dust and noise through enclosed structures and suppression systems. By processing materials directly at the source, they decrease transport-related emissions and support more sustainable production practices.

In sand and gravel aggregate production, mobile impact crushing solutions provide clear advantages in product quality, flexibility, cost efficiency, and environmental performance. Their ability to deliver cubic aggregates while reducing infrastructure and transportation costs makes them a valuable investment for modern producers seeking competitive and sustainable growth.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!