Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

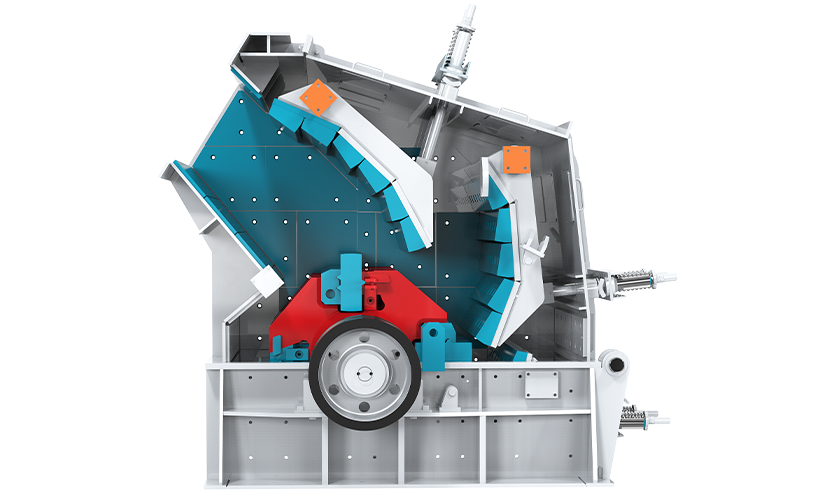

Jaw crushers are among the widely used primary crushing machines in mining, quarrying, and construction industries. They are designed to break large rocks into smaller, manageable sizes through compressive force. A Jaw Crusher Factory typically focuses on producing equipment that is robust, reliable, and suitable for handling hard and abrasive materials. However, like any industrial solution, jaw crusher systems have both strengths and limitations that should be carefully evaluated before selection.

Jaw crushers are often the one choice for primary crushing due to their simple structure and strong crushing capability. Factories specializing in jaw crushers aim to optimize these core advantages.

Jaw crushers are capable of handling very hard materials such as granite, basalt, and iron ore. Their compressive crushing principle allows them to process large feed sizes effectively.

The design of jaw crushers is relatively simple, consisting mainly of a fixed jaw, a movable jaw, and a crushing chamber. This simplicity makes the operation easier and reduces the likelihood of complex mechanical failures.

Products from a well-established Jaw Crusher Factory are known for stable performance under continuous operation. This reliability is especially important in large-scale mining and quarrying projects.

Jaw crushers can process various materials, including natural stone, ores, and construction waste. Their versatility makes them suitable for different industries and working environments.

Due to fewer moving parts, maintenance tasks such as liner replacement and lubrication are relatively straightforward. This reduces downtime and maintenance costs over the long term.

These features improve overall production efficiency when jaw crushers are used as the one step in a crushing line.

Despite their many advantages, jaw crushers also have certain drawbacks that users should be aware of.

Jaw crushers focus on size reduction rather than shaping. The output particles are often flat or elongated, which may require additional shaping equipment for applications requiring high-quality aggregates.

Jaw crushers are not suitable for producing fine materials. Secondary or tertiary crushers are usually required to achieve smaller particle sizes.

When processing highly abrasive materials, jaw plates can wear relatively quickly. Even though factories use wear-resistant materials, regular replacement is still necessary.

Compared to some modern impact-based crushers, jaw crushers can generate higher noise and vibration, which may be a concern in urban or environmentally sensitive areas.

Jaw crushers generally consume more energy during operation due to their crushing principle and heavy-duty design.

From a Jaw Crusher Factory perspective, improvements in motor efficiency and structural optimization have helped reduce energy consumption, but jaw crushers may still use more power compared to certain alternative crushing technologies when producing finer materials.

Jaw crushers are ideal for projects that prioritize durability and the ability to process hard materials. They are commonly used in:

However, for recycling projects or applications that demand high-quality particle shape, additional equipment may be necessary.

When choosing jaw crusher equipment, it is essential to balance its strengths and weaknesses based on project requirements. A professional Jaw Crusher Factory usually provides technical guidance to help customers select the right model and configuration.

Key factors to evaluate include:

Jaw crusher factories offer equipment that is powerful, reliable, and highly effective for primary crushing applications. Their advantages include strong crushing capacity, simple structure, and wide material adaptability. However, limitations such as limited shaping ability, higher wear rates, and noise levels must also be considered.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!