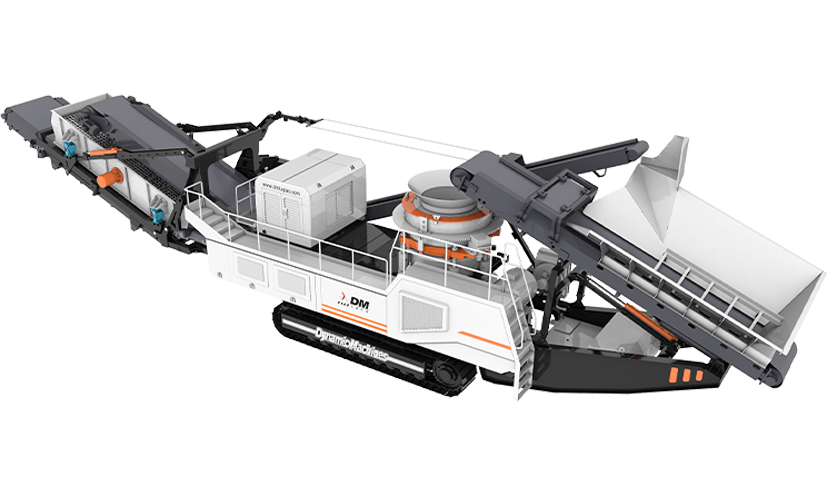

Machinery Weight 55-72t

Max Feeding size(mm) ≤700mm

Hopper Volume(m³) /

Traditional crushing methods usually rely on fixed, single-function machines that operate in isolated stages. Material must be transported multiple times between crushing, screening, and stockpiling areas, which causes inefficiencies. These systems often require extensive civil foundations, long installation periods, and significant labor input. As construction schedules become tighter and labor costs increase, such traditional approaches struggle to meet modern project demands. From the perspective of a Crushing Plant Factory, improving efficiency means rethinking how crushing systems are designed, deployed, and operated on construction sites.

One of the key ways modern crushing plants improve efficiency is through integrated system design. Instead of separate machines working independently, contemporary crushing plants combine multiple functions into a coordinated production line.

This integration significantly shortens processing time compared to traditional setups that depend heavily on manual coordination.

Traditional crushing stations often require complex foundations, steel structures, and long installation cycles. Modern crushing plants are designed with modular and prefabricated components.

From a Crushing Plant Factory design standpoint, this approach offers clear advantages:

Traditional crushing methods often suffer from inconsistent output due to manual adjustments and variable feed conditions. Modern crushing plants are engineered for higher throughput with stable performance.

Key benefits include:

These improvements allow projects to achieve higher output with lower operational costs compared to traditional crushing methods.

Traditional crushing operations often pose safety and environmental challenges. Dust, noise, and unsafe working conditions can disrupt construction schedules.

Modern crushing plants incorporate:

Compared with traditional crushing methods, modern crushing plants significantly improve construction efficiency through integrated design, faster installation, mobility, automation, and stable output quality. By reducing labor intensity, energy consumption, and downtime, these advanced systems help construction projects stay on schedule and within budget. As construction demands continue to rise, innovations driven by the Crushing Plant Factory approach will play an increasingly important role in shaping efficient and sustainable crushing solutions.

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

Just let we know what you want, and we will get in touch with you as soon as possible!