A new type of forehead crusher that has been optimally designed and manufactured in terms of structure, material selection, process, assembly, etc.

Designed for transporting lumpy, granular, and bulk materials across industries, including building materials, metallurgy, and mining. This system excels in handling coarse and fine-grained materials alike, performing reliably in harsh environments while demonstrating exceptional adaptability to variations in material gradation, temperature, viscosity, frost,rain/snow exposure, and frozen aggregates.

Application-Construction waste disposal solution

construction waste

Defined as residual soils, excavated materials, demolition debris, slurry, and other waste

substances generated during construction, demolition, or renovation activities by construction units or individuals on buildings, structures, pipelines, and related infrastructure.

Solution description:

Our system utilizes hydraulic jaw crushers, large-diameter impact crushers, high frequency composite screens, and lightweight material sorting equipment to execute a streamlined conversion process.

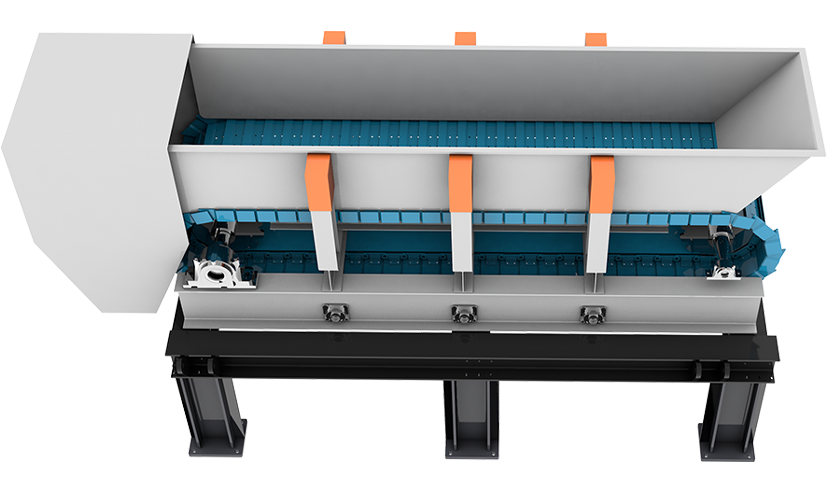

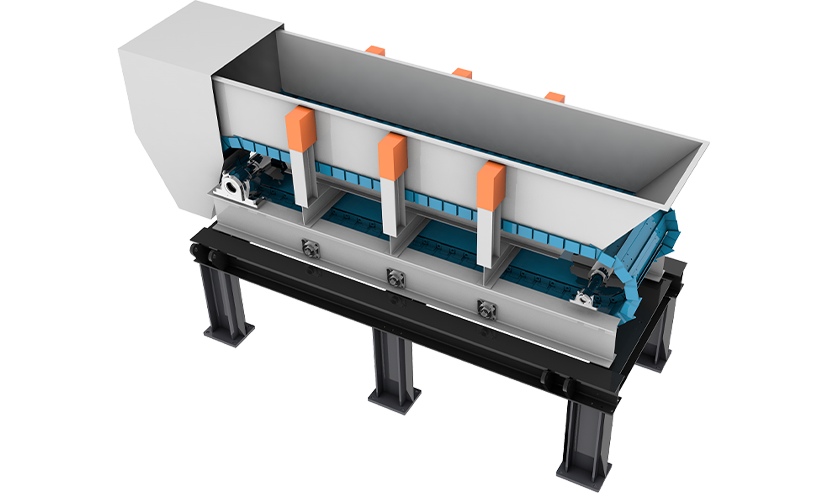

Performance Requirements for Apron Feeders

• Apron Feeder BZ1200*6: No special performance requirements.

• Apron Feeder DMBL1238: The feed hopper is installed on the upper part and the discharge hopper on the front part; The frame shall have good rigidity and load-bearing capacity, and possess excellent resistance to instantaneous material impact.

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский