A new type of forehead crusher that has been optimally designed and manufactured in terms of structure, material selection, process, assembly, etc.

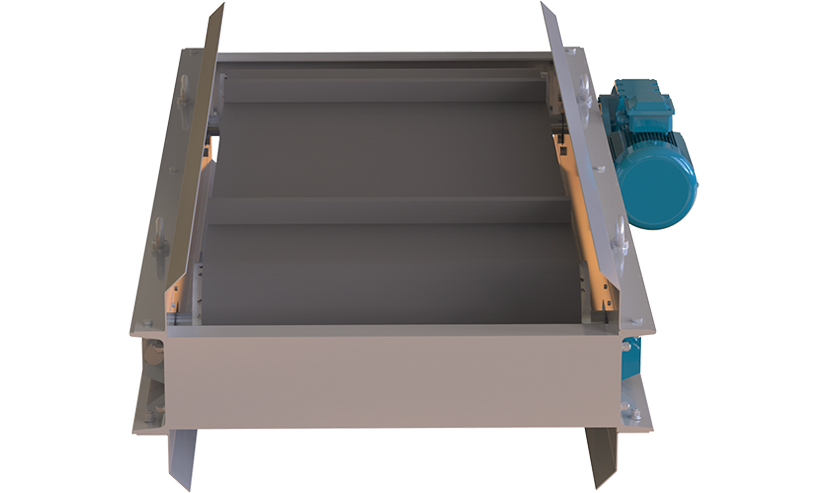

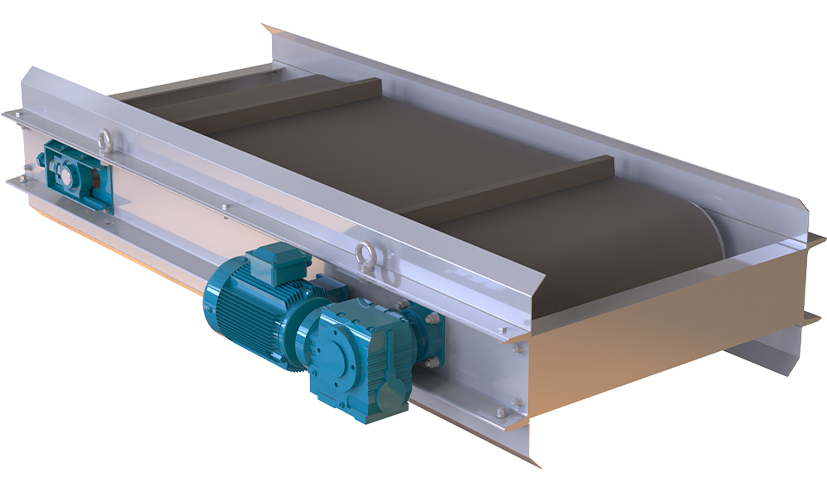

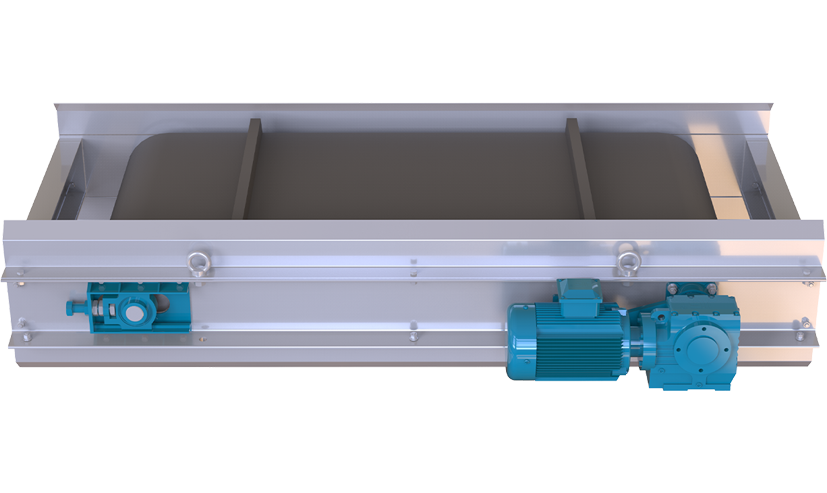

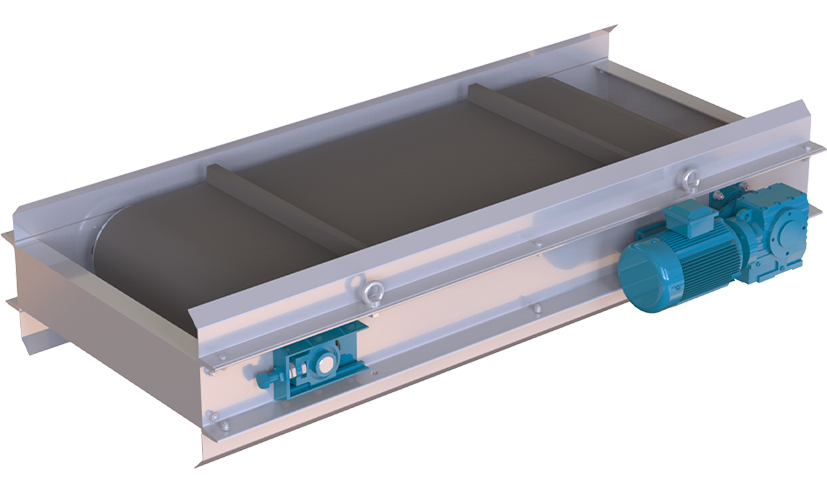

Industrial self-discharging magnetic separator

-

Feed Particle Size

Subject to actual circumstances -

Processing Capacity

Subject to actual circumstances -

Machinery Weight

Subject to actual circumstances

- Product Introduce

- Advantages

- Application & Case

- Technical Parameters

Equipment Device

Advantages & Highlights

-

Internal magnetic circuit

The internal magnetic circuit was designed using computer simulation.

-

Dual-pole structure

Advanced dual-pole structure delivers high magnetic field strength, significant gradient, and powerful magnetic attraction.

-

Automatic Correction

Automatic alignment correction function, fully sealed bearing housing, excellent sealing performance.

-

Automatic iron removal

The automatic belt iron removal system ensures trouble-free, long-term operation of the entire machine in harsh environments.

Technical Parameters

| Equipment Name | Parameter Item | Parameter Content |

| Self Discharging Magnet Separator RCYD-10 | Iron Remover Belt Width | 1000mm |

| Rated Lifting Height | ≤300mm | |

| Driving Power | 3kw | |

| Maximum Applicable Belt Speed | ≤4.5m/s | |

| Rated Voltage | 380V | |

| Rated Frequency | 50Hz | |

| Drive Motor Brand / Protection Class | Guomao or Kaili; IP55 | |

| Pressure Range | 4454-3012Pa | |

| Self Discharging Magnet Separator B=800/650 | Equipment Model / Belt Width | RCYD-8 / RCYD-6.5; 800mm / 650mm |

| Rated Lifting Height | ≤300mm | |

| Driving Power | 3kw/2.2kw | |

| Iron Removal Form | Permanent Magnet | |

| Maximum Applicable Belt Speed | ≤4.5m/s | |

| Rated Voltage | 380V | |

| Rated Frequency | 50Hz | |

| Magnetic Field Strength | ≥70mT |

You may also like

-

Mobile impact crushing station

Machinery Weight 53-62t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) 80-360t/h

-

Mobile cone crushing station

Machinery Weight 55-57t

Max Feeding size(mm) ≤215mm

Hopper Volume(m³) /

-

Mobile screening station

Machinery Weight 33-35t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 2.5

-

Mobile heavy screening station

Machinery Weight 33t

Max Feeding size(mm) 150-400t/h

Hopper Volume(m³) 7m³

-

Mobile counterattack all-in-one machine

Machinery Weight 54-63t

Max Feeding size(mm) ≤600mm

Hopper Volume(m³) /

-

DC series high efficiency european jaw crusher

Machinery Weight 9.5-75t

Max Feeding size(mm) ≤1000mm

Hopper Volume(m³) 61-1204t/h

high-tech enterprises

Modern intelligent processing base integrating R&D, production and sales.

-

0+ Year

Industry Experience

-

0 M²

Factory Space

-

0+

Employees

-

0+

Sets of Equipment

-

0+

Global Business

Latest Insights & NEWS

Our team of engineers has carefully polished and cast stationary and mobile production line solutions for many years.

-

Materials Suitable for Stone Crushing Machine Applications

Understanding the Role of Stone Crushing Machines Stone crushing machines are essential equipment in mining, quarrying, construction, and recycling industries. Their primary function is to reduce larg...

-

Advantages of Mobile Impact Crushers for Construction Waste Recycling

Increasing Pressure to Recycle Construction Waste With the acceleration of urban renewal and infrastructure upgrades, construction and demolition waste has become a major environmental challenge. Larg...

-

Performance of Stone Crushing Machine Factory with Wet Materials

Introduction to Wet Material Challenges A Stone Crushing Machine Factory produces equipment designed to handle a variety of rocks, ores, and aggregates. One of the common operational challenges is pro...

-

Advantages and Disadvantages of Mobile Crusher Factory Equipment

Introduction to Mobile Crusher Factory A Mobile Crusher Factory specializes in producing mobile crushing equipment designed for flexible, on-site material processing. Compared to traditional fixed cru...

-

Types of Rocks and Ores Processed in Stone Crusher Factory

Introduction to Stone Crusher Factory Operations A Stone Crusher Factory produces crushing equipment designed to handle a wide variety of rocks and ores. Understanding the types of materials that can ...

-

Differences Between Cone Crusher Factory and Traditional Machines

Introduction to Modern Cone Crusher Factories A Cone Crusher Factory specializes in designing and producing advanced cone crushers for the mining, aggregate, and construction industries. These modern ...

Contact Us for Quotes and Prices!

Just let we know what you want, and we will get in touch with you as soon as possible!

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский