A new type of forehead crusher that has been optimally designed and manufactured in terms of structure, material selection, process, assembly, etc.

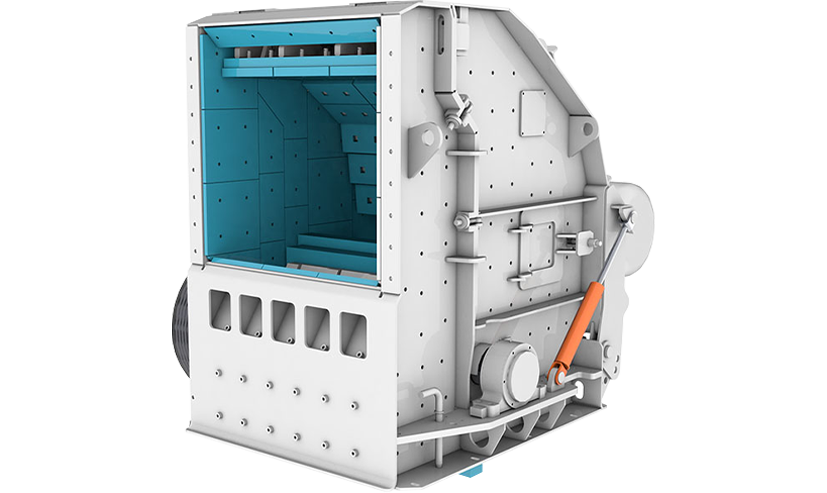

Hydraulic large diameter impact crusher adopts unique designs such as heavy rotor, large-capacity crushing chamber, thick impact plate, high-wear-resistant alloy blow bar, hydraulic opening device, etc. It has the advantages of greater crushing capacity and crushing ratio, low operating cost and convenient maintenance.

Application-Construction waste disposal solution

construction waste

Defined as residual soils, excavated materials, demolition debris, slurry, and other waste substances generated during construction, demolition, or renovation activities by construction units or individuals on buildings, structures, pipelines, and related infrastructure.

Solution description:

Our system utilizes hydraulic jaw crushers, large-diameter impact crushers, high frequency composite screens, and lightweight material sorting equipment to execute a streamlined conversion process.

Performance Requirements for Impact Crushers

• Impact Crusher (DMI1313): Impact crushing; Sealing treatment for feed and discharge ports of the anti-impact crusher to prevent dust leakage; Bearing seats are cast integrally with cast steel; Rotors adopt segmented welding process; Full hydraulic adjustment is used, including hydraulic station, hydraulic iron remover, hydraulic adjustment of discharge port, and hydraulic cover opening.

• Impact Crusher (DMI1013): No additional special performance requirements specified (main requirements are reflected in technical parameters).

简体中文

简体中文 English

English Français

Français Español

Español عربي

عربي Русский

Русский